Composite Geomembrane

Classification :

PRODUCT DETAILS

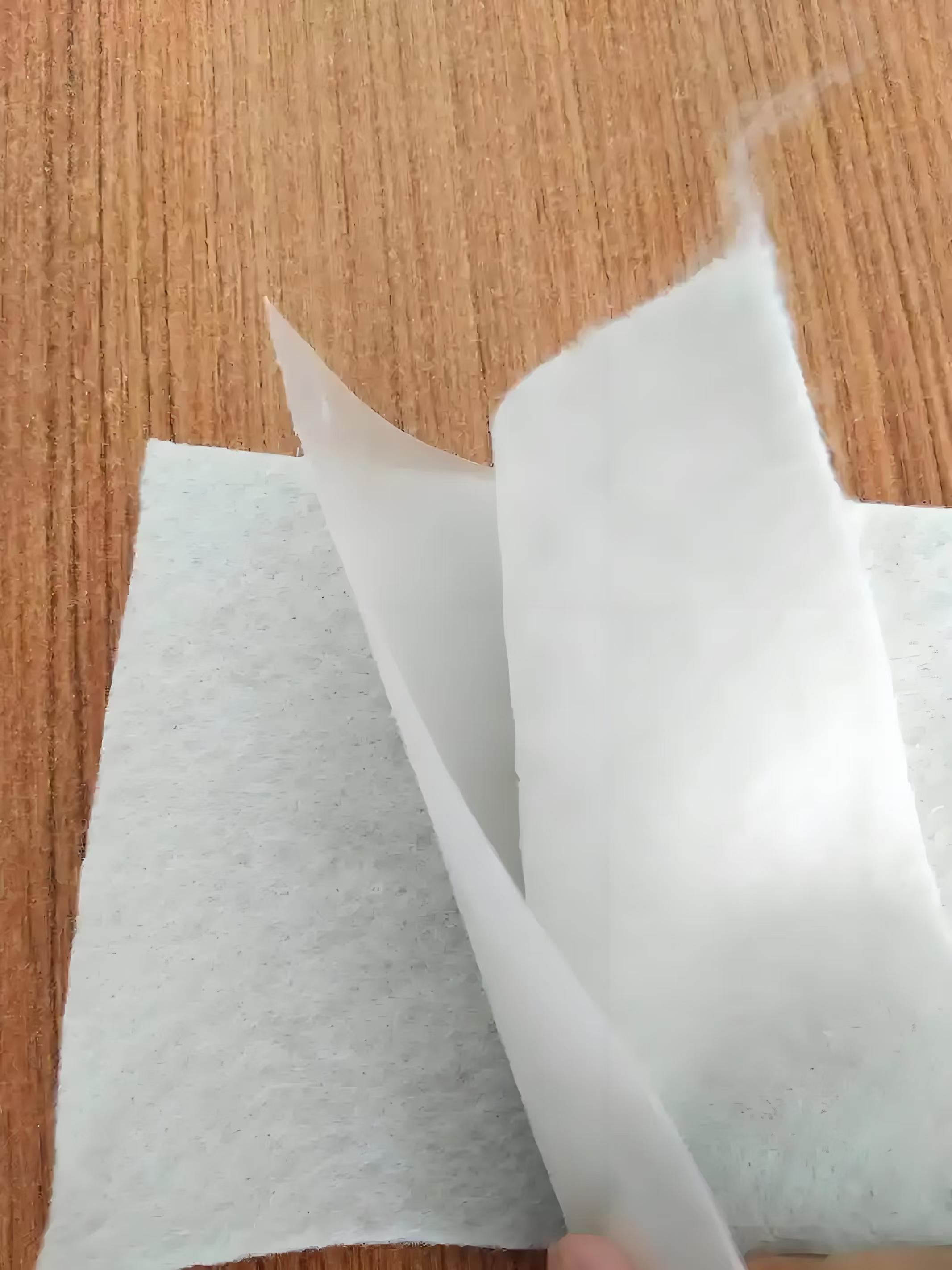

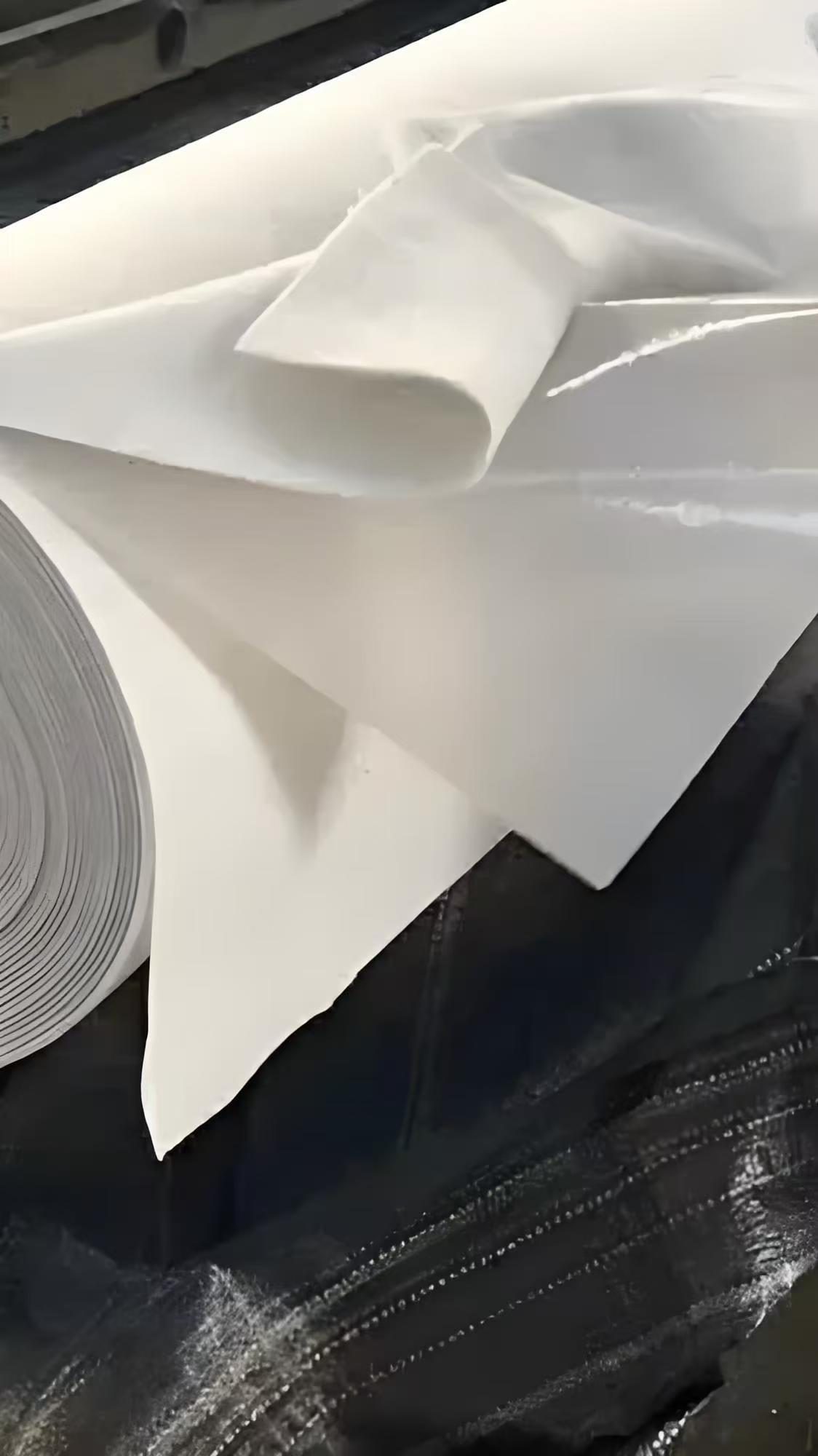

Composite geomembrane is an impermeable material composed of geotextile and geomembrane, mainly used for anti-seepage. It is divided into two types: one fabric and one film and two fabrics and one film. Composite geomembranes are mainly made of polymer materials such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE). It is usually composed of plastic film (such as PE film) and non-woven fabric composite. Plastic film serves as the anti-seepage substrate, while non-woven fabric increases the tensile strength and puncture resistance of the film, while improving the stability of the composite material.

Specification of composite geomembrane

Thickness specification:

Common thickness range: 0.2mm-2.0mm

One cloth, two films: film thickness 0.1-1.5mm

One cloth, one film: film thickness 0.1-1.5mm

Two fabrics and one film: film thickness 0.2-1.5mm

Width specification:

Common width: 1m-6m. Other sizes can also be customized

Using base cloth:

1. Main base fabric: needle punched non-woven geotextile, and can also be used with machine woven fabric, plastic woven fabric, etc. according to user requirements

2. Weight range of base fabric: 100-1000g/m ²

Main characteristics of composite geomembrane

High strength and durability: Composite geomembranes have high strength and excellent durability, capable of withstanding large loads and resisting external damage. Its tensile strength at break is as high as 28MPa, the elongation at break can reach 700%, and the material has a service life of up to 50-70 years.

Excellent anti-seepage performance: Composite geomembranes have excellent anti-seepage performance, which can effectively prevent water infiltration and reduce soil erosion. Its anti-seepage coefficient is higher than that of traditional waterproof materials, and it is suitable for occasions that require strict anti-seepage, such as water conservancy dams, landfills, and sewage treatment plants.

Convenient and cost-effective construction: The construction methods of composite geomembranes are diverse, including hot melt, cold bonding, and other methods, with fast and convenient construction speed. Its high flexibility enables it to meet the anti-seepage requirements of different projects, and in actual engineering, it can usually save about 50% of costs.

Widely applicable fields: Composite geomembranes not only perform well in hydraulic engineering, but also have been widely used in various fields such as transportation engineering, environmental protection, agriculture and horticulture, mining construction, petrochemical industry, aquaculture, etc.

Environmentally friendly and non-toxic: The composite geomembrane uses non-toxic and environmentally friendly materials, and its anti-seepage principle is based on ordinary physical changes, without producing any harmful substances. It is suitable for environmental protection, aquaculture, drinking water tanks and other occasions.

Application field of composite geomembrane

The application fields of composite geomembranes are very wide, mainly including the following aspects:

Water conservancy engineering: Composite geomembranes have a wide range of applications in water conservancy engineering, such as dam foundation reinforcement, drainage of groundwater by drainage plates, and pressure reduction through drainage. It is also used for river slope protection, artificial lakes, and sightseeing lake projects, which can effectively prevent water leakage and protect the safety of water conservancy projects.

Environmental Protection Engineering: In the field of environmental protection, composite geomembranes are used for urban solid waste treatment to prevent pollution from spreading and protect the environment. In addition, it is also used for foundation anti-seepage and pollution prevention in waste residue treatment plants.

Municipal construction engineering: In municipal construction engineering, composite geomembranes are used for soft soil foundation reinforcement and drainage to improve the safety and stability of the project.

Petrochemical system: In the petrochemical system, composite geomembranes are used for anti-seepage and anti-corrosion of chemical wastewater tanks, refinery wastewater tanks, etc., to ensure the safety and environmental protection of chemical production.

Road traffic facilities: In road traffic facilities, composite geomembranes are used for anti-seepage and diversion reinforcement under ballast, anti-seepage reinforcement of culverts and tunnels, and underground water drainage to protect circuits from moisture.

Aquaculture industry: In the aquaculture industry, composite geomembranes are used for anti-seepage of facilities such as lotus ponds to improve aquaculture efficiency.

Index coefficient of composite geomembrane

The index coefficients of composite geomembranes mainly include the following aspects:

Thickness: The thickness of composite geomembrane is generally between 0.1mm and 4.0mm, depending on the application requirements.

Fracture strength: The fracture strength of composite geomembranes is usually between 10KN/m and 16 kN/m, depending on the material and design requirements.

Elongation at break: Elongation at break represents the ability of a material to stretch to fracture, typically around 68%.

Breaking strength: The CBR breaking strength is generally around 1.9KN.

Tear strength: The tear strength is usually around 0.32KN.

Peel strength: Peel strength refers to the tensile strength of a material during the peeling process, generally around 6N/m.

Physical and mechanical performance indicators of composite geomembrane

Composite geomembranes have the characteristics of high strength, high elongation performance, large deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, and good anti-seepage performance. Its physical and mechanical performance indicators include tensile strength, tear resistance, and burst resistance, which ensure its stability and durability in various engineering applications.

Construction process

Soil surface treatment: Before construction, the soil surface needs to be leveled, cleaned, and drained to ensure that the soil base surface is dry, flat, free of accumulated water and impurities.

Composite geomembrane laying: Lay the composite geomembrane according to the predetermined width and length, keeping it flat and leaving a certain margin.

Welding joints: Use a hot air gun or high-frequency welding machine to weld the joints of composite geomembranes, ensuring that the welding is firm and leak free.

Fixed edge: At the edge of the composite geomembrane, U-shaped groove nails or other fasteners are used for fixation to ensure that the composite geomembrane does not shift.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.