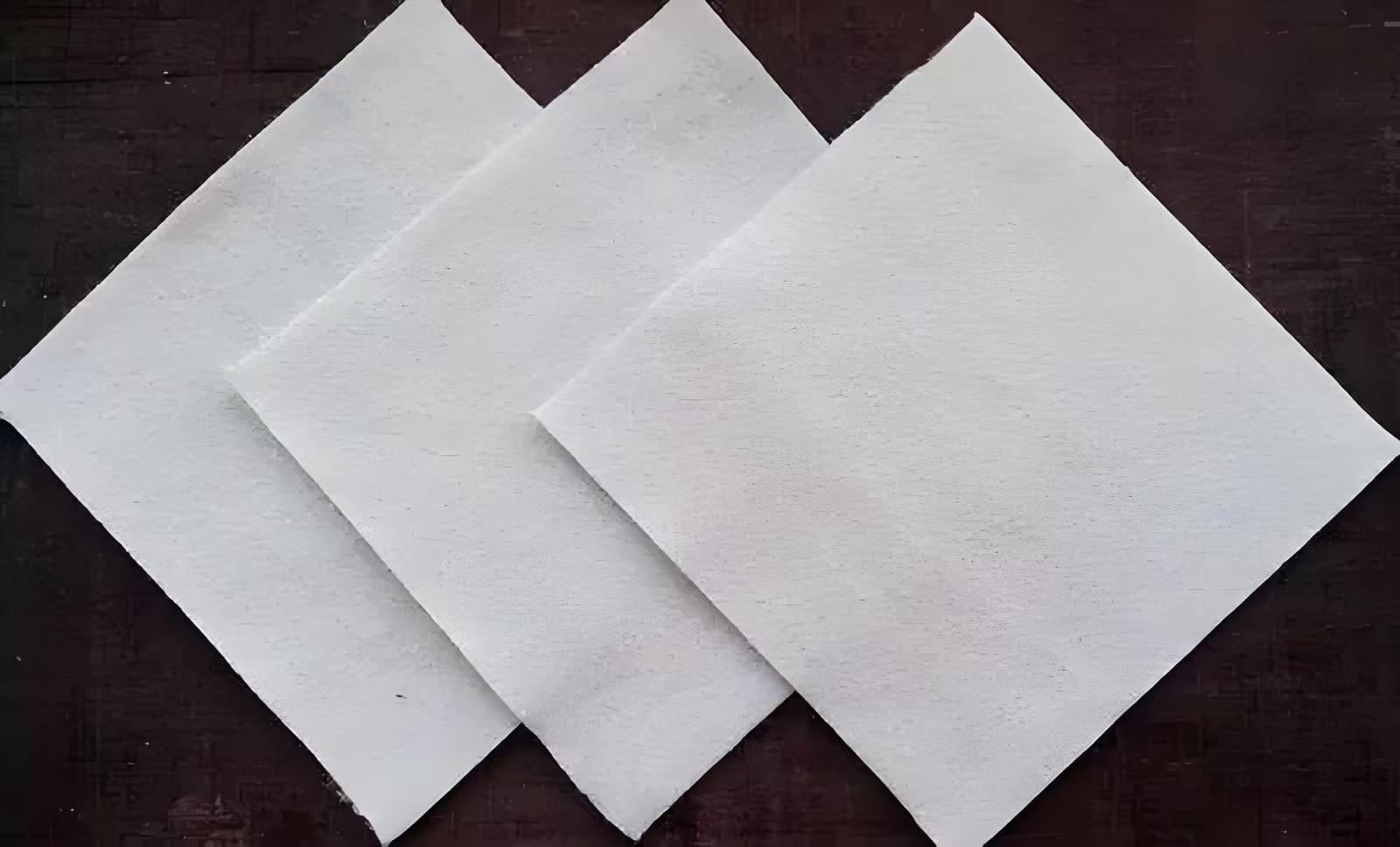

Short Fiber Geotextile

Classification :

PRODUCT DETAILS

Short fiber geotextile is a non-woven and industrial fabric made from polyester curled short fibers with a fiber fineness of 6-12 deniers and a length of 54-64mm. It is produced into a fabric shape through non-woven production equipment such as opening, combing, laying, and needle punching. Short fiber geotextile has good breathability, permeability, and high strength, and is widely used in the reinforcement of railway subgrades, maintenance of highway pavements, protection of dams, isolation of hydraulic structures, and other fields.

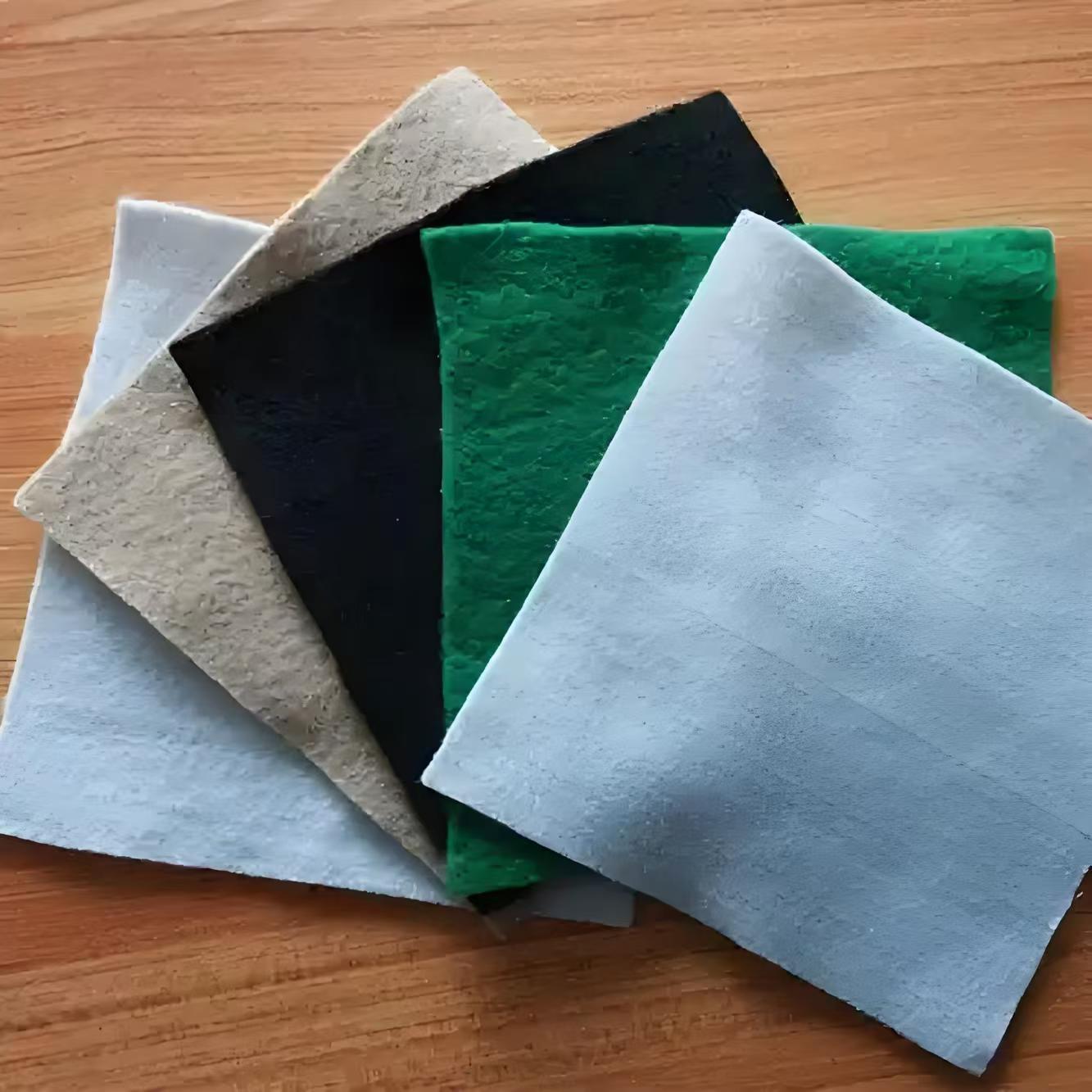

classification

Short fiber geotextiles can be divided into polyester short fiber geotextiles and polypropylene short fiber geotextiles according to fiber raw materials.

Specifications

100g/㎡ to 800g/㎡

The specification range of short fiber geotextile is 100g/㎡ to 800g/㎡. Common specifications include 100g/㎡, 200g/㎡, 300g/㎡, 400g/㎡, 500g/㎡, and 600g/㎡, etc

The width is generally 2m to 6m, and the length is generally 30m to 100m, which can also be customized according to customer needs. In addition, the common width in the market is 6m, and the length is generally 50m.

The main characteristics of short fiber geotextile include the following aspects:

High strength: Short fiber geotextile has high tensile strength and tear resistance, which can provide good support and protection.

Corrosion resistance: This material has good corrosion resistance to various chemical media and can be used for a long time in corrosive or polluted environments.

Good permeability: Short fiber geotextile has large internal voids, which can effectively dissipate water to groundwater or rainwater, and has good drainage and drying properties.

Antimicrobial properties: Short fiber geotextiles have good resistance to microorganisms and insect infestations.

Convenient construction: Due to its lightweight and flexible material, it is easy to transport, lay, and construct, making it suitable for various terrains and complex landforms.

Complete specifications: The width can reach 6 meters, and the unit area mass is between 100-600g/㎡.

The application areas of short fiber geotextile include:

Water conservancy, embankment, road construction, airport, construction, environmental protection engineering: In these projects, short fiber geotextile is mainly used for filtration, drainage, isolation and protection, as well as reinforcement.

Reinforcement of railway subgrade: In railway subgrade construction, short fiber geotextile can provide additional support and stability.

Maintenance of highway pavement: In the maintenance of highway pavement, short fiber geotextile helps to improve the durability and stability of the pavement.

Isolation of sports facilities and hydraulic structures: Short fiber geotextiles are used for isolation and protection in sports facilities and hydraulic structures to ensure structural stability and safety.

Coastal beach and reclamation project: in coastal mudflat and reclamation project, short wire geotextile is used to prevent soil erosion and protect coastline.

The main parameters of short fiber geotextile are as follows

The main parameters of short fiber geotextile include weight, tension, thickness, etc.

Weight and tension

The weight range of short fiber geotextile is usually between 100g/㎡ and 1000g/㎡. Taking 100 grams as an example, the tensile strength of national standard short silk fabric is 2.5KN, while the tensile strength of long silk fabric is 4.5KN. The tensile strength of long silk fabric is much greater than that of short silk fabric by 12.

Thickness

The thickness of short fiber geotextile varies depending on its weight. For example, the thickness of 300g short fiber geotextile is 2.4mm, the thickness of 400g short fiber geotextile is 3mm, and the thickness of 500g short fiber geotextile is 3.3mm3.

Physical property

The physical properties of short fiber geotextile include fracture strength, elongation, and CBR bursting strength. For example, the fracture strength of 400g/㎡ long filament geotextile is 20kn/m, the elongation is 40-80%, and the CBR bursting strength is 0.56KN

The construction of geotextile mainly includes the following steps:

1. Preparation work: Firstly, it is necessary to clean and level the construction site to ensure that the soil surface is flat and free of debris. Then, according to the needs of the project, select suitable geotextile materials.

2. Laying geotextile: Spread the geotextile along the direction of the area to be reinforced and fix it to the soil surface with fixtures such as U-shaped main nails, U-shaped cement bricks, etc. The laying of geotextile should leave overlapping areas and ensure that the edges are completely covered.

3. Fix the geotextile: nail or fix it and rotate it about 30 degrees to avoid puncturing the geotextile.

4. Connecting geotextiles: At the overlapping parts of adjacent geotextiles, use hot-melt glue or special joint materials to connect them, ensuring that there are no gaps.

5. Soil filling reinforcement: Soil filling reinforcement can be carried out above the geotextile, using gravel or sand to increase the fixation and compressive performance of the geotextile.

6. Compaction of soil and fixation of geotextile: During the process of filling soil, attention should be paid to timely compaction to ensure good bonding between soil and geotextile, and further fixation of geotextile with fixtures should be used to ensure construction quality.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.