PRODUCT DETAILS

HDPE geomembrane is one of the geosynthetic materials, also known as high-density polyethylene film, HDPE geomembrane, or HDPE impermeable membrane. Its English name is "High Density Polyethylene Impermeable membrane", abbreviated as "HDPE membrane". HDPE is a thermoplastic resin with high crystallinity and non plasticity. The original appearance of HDPE is milky white, with a certain degree of semi transparency in the thin section. HDPE has excellent anti-corrosion performance, electrical performance, moisture resistance, leakage resistance, and high tensile strength (geomembranes with a density of 0.94g/cm3 or above).

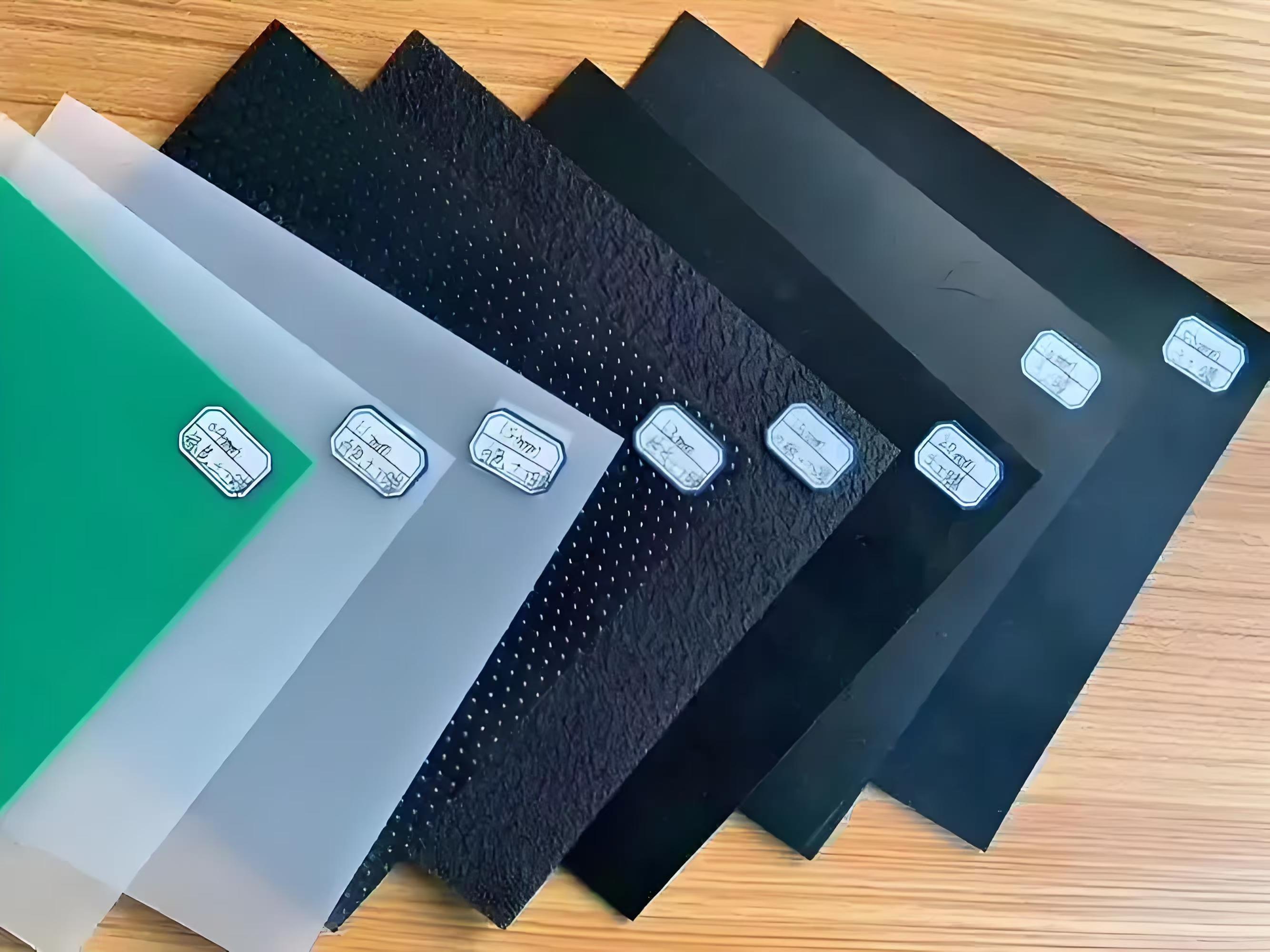

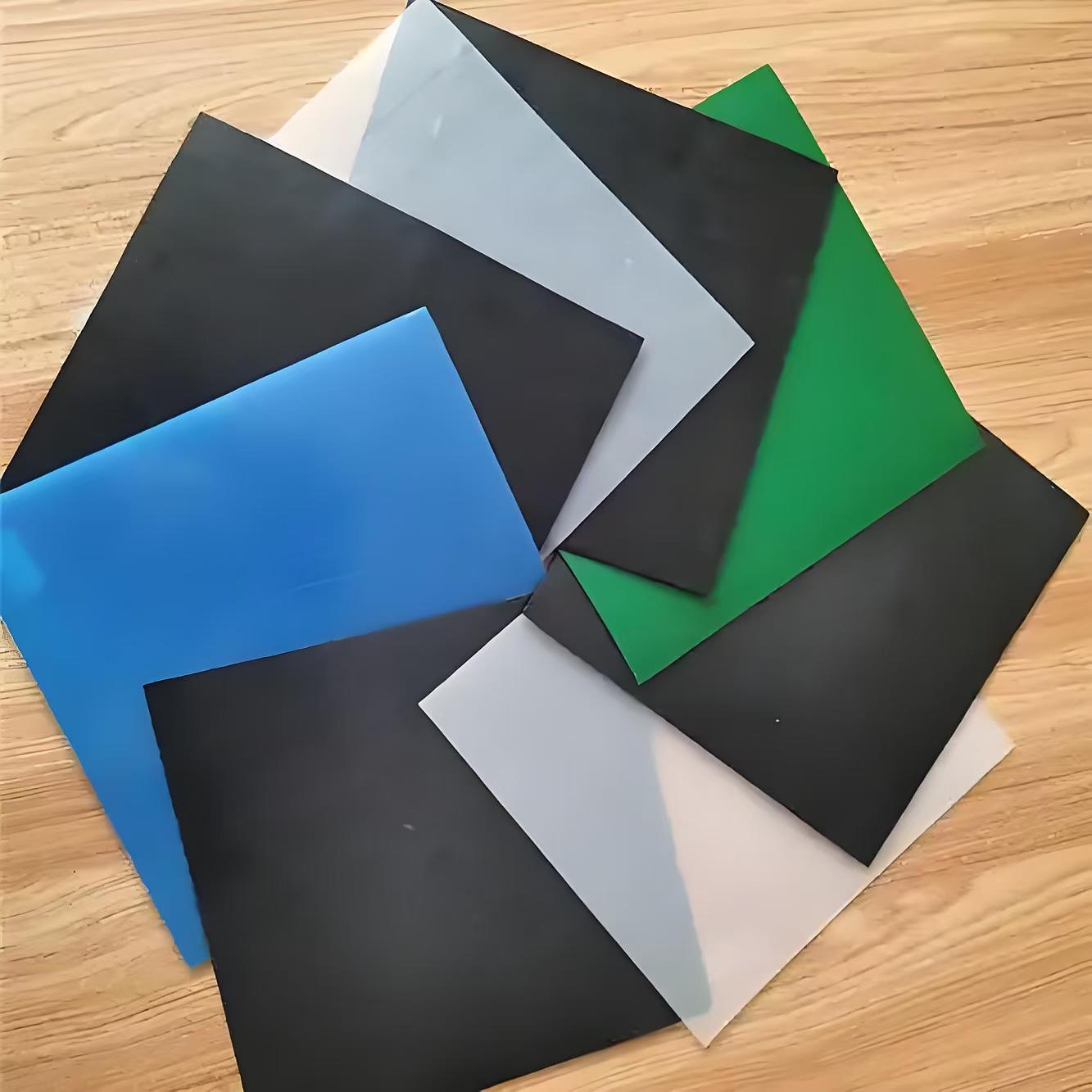

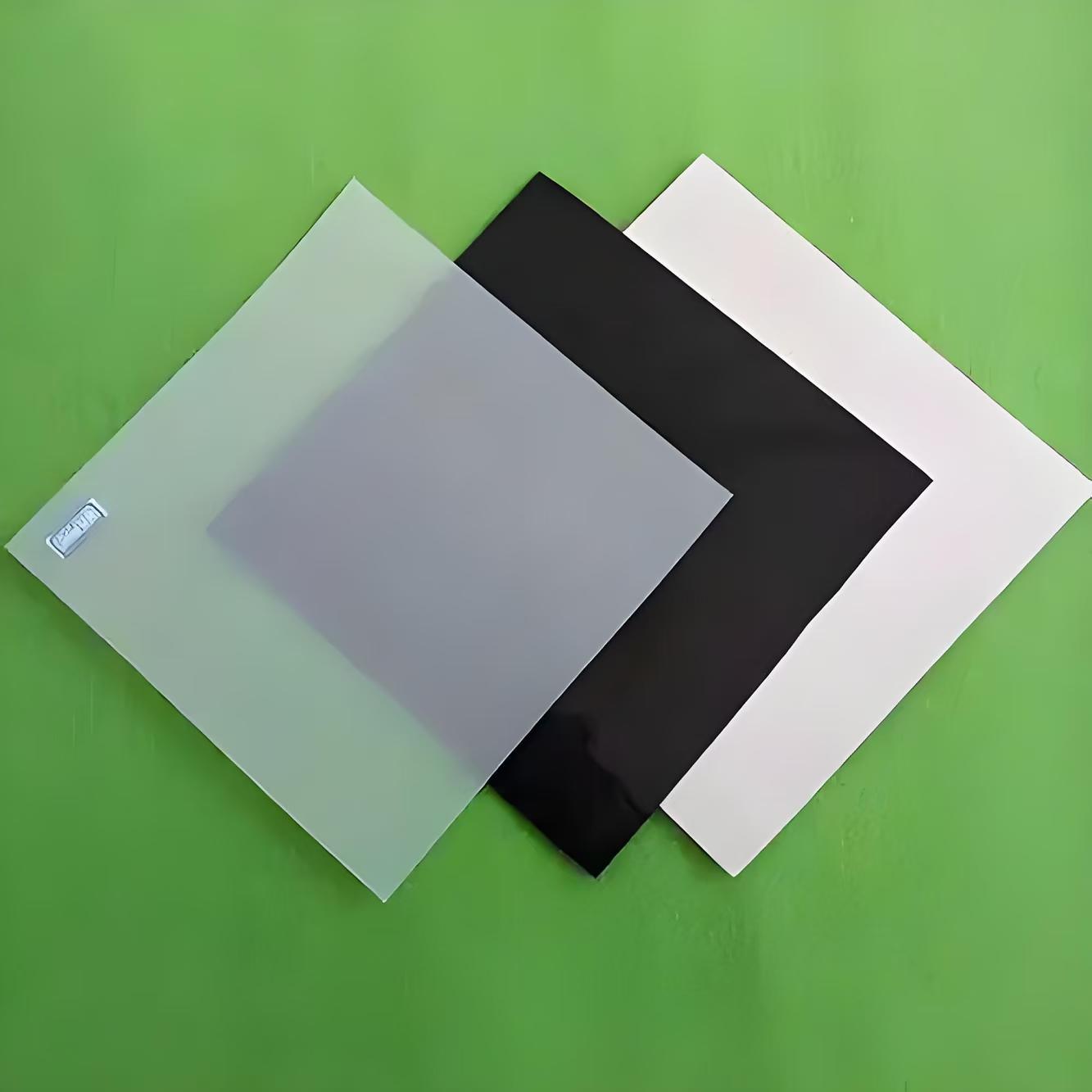

Specifications:

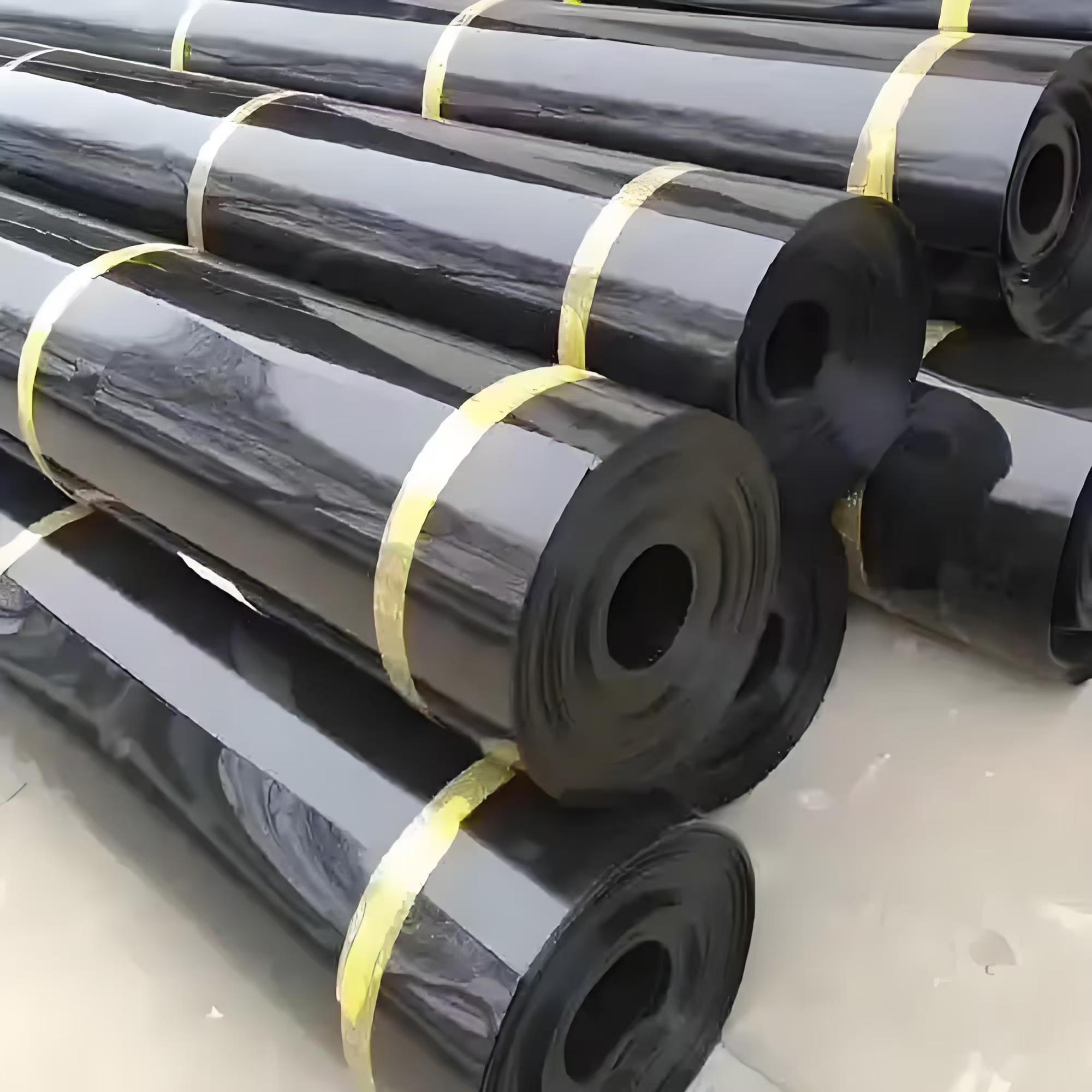

Conventional width: 6m width (customizable for 1-6 meters)

Regular length: 50 meters (customizable)

Thickness: 0.2mm-3.0mm

Color: Black, White, Blue, Green (customizable)

Keywords: plastic film, HDPE plastic film, pond lining, waterproof film, 0.5mm plastic film, 1.0mm plastic film, plastic film lining, HDPE lining, landfill lining, plastic film, shrimp pond lining, tailings pond plastic film

Performance characteristics:

Good anti-seepage performance: water vapor permeability coefficient K ≤ 1.0 × 10 g.cm/(cm. s.paa).

High strength: Tensile strength at break ≥ 28MPa.

Long service life: The material can have a service life of over a hundred years.

◎ Low temperature resistance: Cold brittleness temperature -66 ℃~77 ℃.

◎ Corrosion resistance: capable of withstanding corrosion from over 80 types of strong acid and alkali lamp chemicals.

◎ Non toxic and harmless: harmless to human body, does not pollute the environment, widely used in drinking water projects abroad.

Good economic benefits: low total cost, low investment. Good welding performance: pad welding, high weld strength.

Function and purpose:

Environmental protection projects such as garbage disposal sites, sewage treatment plants, petrochemicals, metallurgy, etc;

Water conservancy projects such as reservoirs, dams, rivers, lakes, etc;

◎ Subway, tunnel, underground warehouse, etc;

Artificial lakes, scenic spots, and other landscaping projects;

The construction market and other waterproofing projects.

Landfill: High density polyethylene geomembrane is commonly used as an inner lining for landfills to prevent leachate from contaminating groundwater. Leachate contains substances that are harmful to the environment.

Ponds and lagoons: They are used as linings in decorating ponds, fish ponds, lagoons, and artificial lakes to prevent water leakage to the ground.

Reservoirs and storage tanks: They are also used as linings for reservoirs, storage tanks, and other facilities that store water, other liquids, and even gases.

Canal: High density polyethylene geomembrane is commonly used for lining canals, ditches, or other waterways to prevent soil erosion.

Mining industry: In the mining industry, they are used as linings for tailings ponds and leaching ponds to prevent pollution of the surrounding environment.

Agriculture: In agriculture, they can be used to irrigate ditches, farm ponds, and even to fill manure lagoons.

Construction: It can be used as a moisture-proof layer under concrete slabs or inside basement walls to prevent moisture from entering.

Environmental remediation: They are used in environmental remediation projects to contain pollutants or prevent their spread to neighboring areas.

Oil and gas industry: They can be used for secondary sealing of fuel storage tanks to prevent any potential leakage and pollution of the surrounding environment.

Aquaculture: In aquaculture, high-density polyethylene geomembrane is used in fish and shrimp ponds to maintain water quality and prevent diseases.

The above are just a few examples, and the use of high-density polyethylene geomembrane may vary greatly depending on the specific requirements of the project.

Construction plan specifications:

Do not drag or forcefully pull the geomembrane during transportation to avoid sharp objects from puncturing it.

1. It should extend from the bottom to the high position, without pulling too tightly, leaving a margin of 1.50% for local sinking and stretching. Considering the actual situation of this project, the slope will be laid in a top-down sequence;

2. The longitudinal joints of adjacent frames should not be on the same horizontal line and should be staggered by more than 1m from each other;

3. The longitudinal joint should be at least 1.50m away from the dam foot and bend foot, and should be set on a flat surface;

4. First, the bottom of the slope;

5. When laying the slope, the direction of the film should be basically parallel to the maximum slope line.

Serial Number | Project | Index | ||||

|

| LDPE | LLDPE | EVA | HDPE |

|

Ordinary | Environmental protection |

|

|

|

|

|

1 | thicknessmm | 0.2-3.0 | 0.2-3.0 | 0.2-4.0 | 0.2-4.0 |

|

2 | widthm | 2.5-9.0 | 2.5-9.0 | 2.5-8.0 | 2.5-8.0 |

|

3 | Tensile strength (longitudinal and transverse)Mpa | >=14 | >=16 | >=16 | >=17 | >=25 |

4 | Tensile elongation at break (longitudinal and transverse)% | >=400 | >=700 | >=550 | >=450 | >=550 |

5 | Right angle tear strength N/mm | >=50 | >=60 | >=60 | >=80 | >=110 |

6 | Water vapor permeability coefficientg.cm/㎡.s.pa | <1.0*10 | <1.0*10 | <1.0*10 | —— | —— |

7 | Temperature range for use

| +70℃--709C | +70℃--709C | +70℃--709C | —— | —— |

8 | Carbon black content% | —— | —— | —— | 2.0-3.0 |

|

9 | Resistant to environmental stress cracking F

| —— | —— | —— | >=1500 |

|

10 | Low temperature impact embrittlement performance at 70 ℃ | —— | —— | —— | pass |

|

11 | 200 ℃ oxidation induction time | —— | —— |

|

| |

(1) The average values of maneuvering direction (MD) and maneuvering lateral direction (XMD) should be based on 5 samples in each direction

The yield elongation is calculated using a sample length of 33 mm.

The elongation at break is calculated using a specimen length of 50 mm.

(2) The yield stress used to calculate the applied load for SP-NCTL testing should be the average value obtained by the manufacturer through MQC testing.

(3) Other methods, such as D1603 (tube furnace) or D6370 (TGA), are acceptable if they can establish appropriate correlation with D4218 (muffle furnace).

(4) 10 different views of carbon black dispersion (only near spherical aggregates): 9 in category 1 or 2 and 1 in category 3

(5) Manufacturers can choose any of the listed OIT methods to evaluate the antioxidant content in soil films.

(6) It is also recommended to evaluate the samples at 30 and 60 days and compare them with the response at 90 days.

(7) The experimental conditions are: UV light cycling at 75 ° C for 20 hours, followed by condensation at 60 ° C for 4 hours.

(8) Not recommended for use as the high temperature of the standard OIT test can produce unrealistic results for certain antioxidants in UV exposed samples.

(9) The UV resistance performance is based on the percentage of retention value, without considering the original HP-OIT value.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.