PRODUCT DETAILS

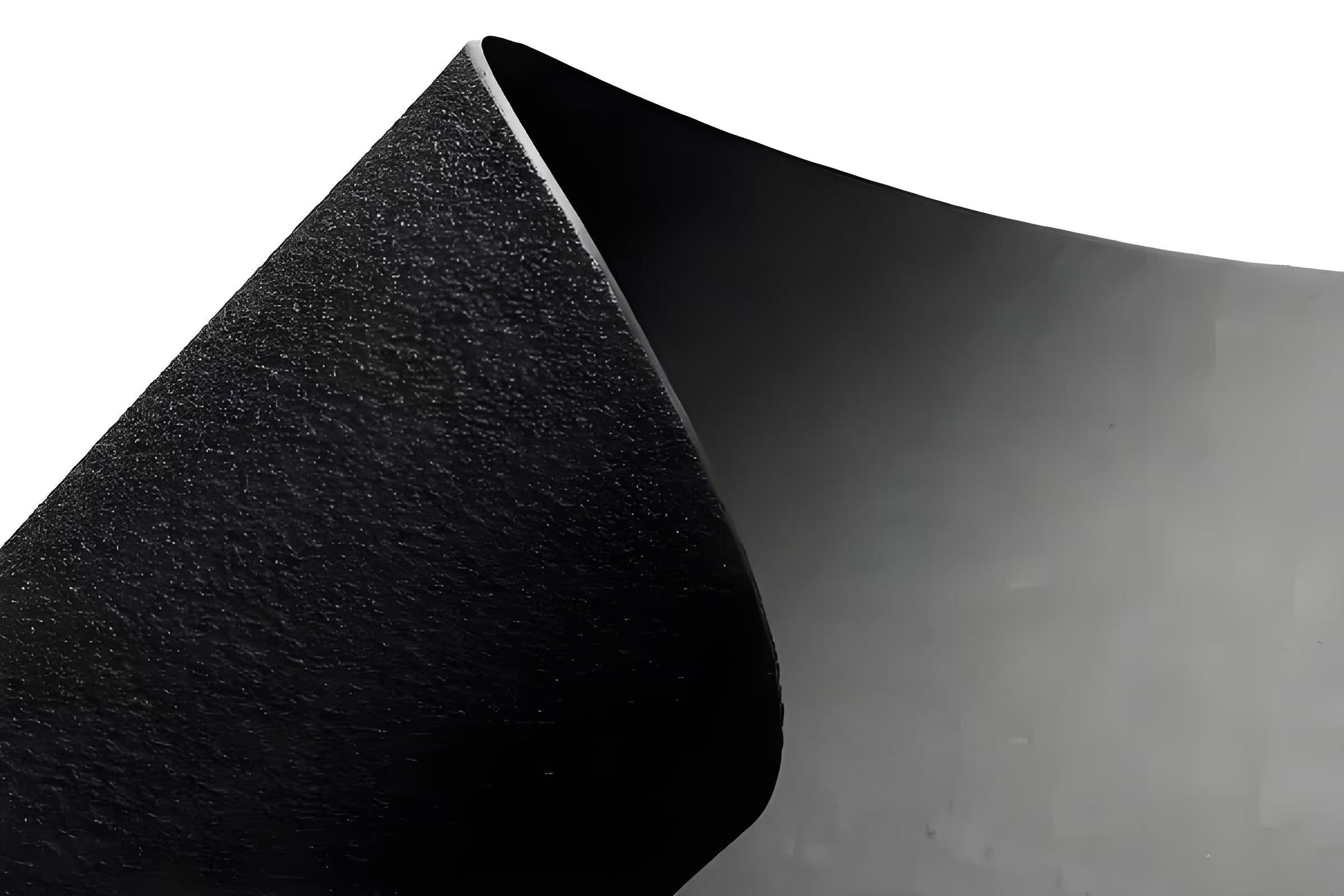

HDPE rough surface geomembrane is a type of HDPE geomembrane, which is mainly divided into HDPE single rough surface geomembrane and HDPE double rough surface geomembrane. Among them, HDPE single rough surface geomembrane is a HDPE geomembrane with one rough surface, while HDPE double rough surface geomembrane is a HDPE geomembrane with both rough surfaces. HDPE rough surface geomembrane, due to its unique appearance characteristics, has high friction and can be applied to slope seepage prevention in various engineering projects.

Specifications:

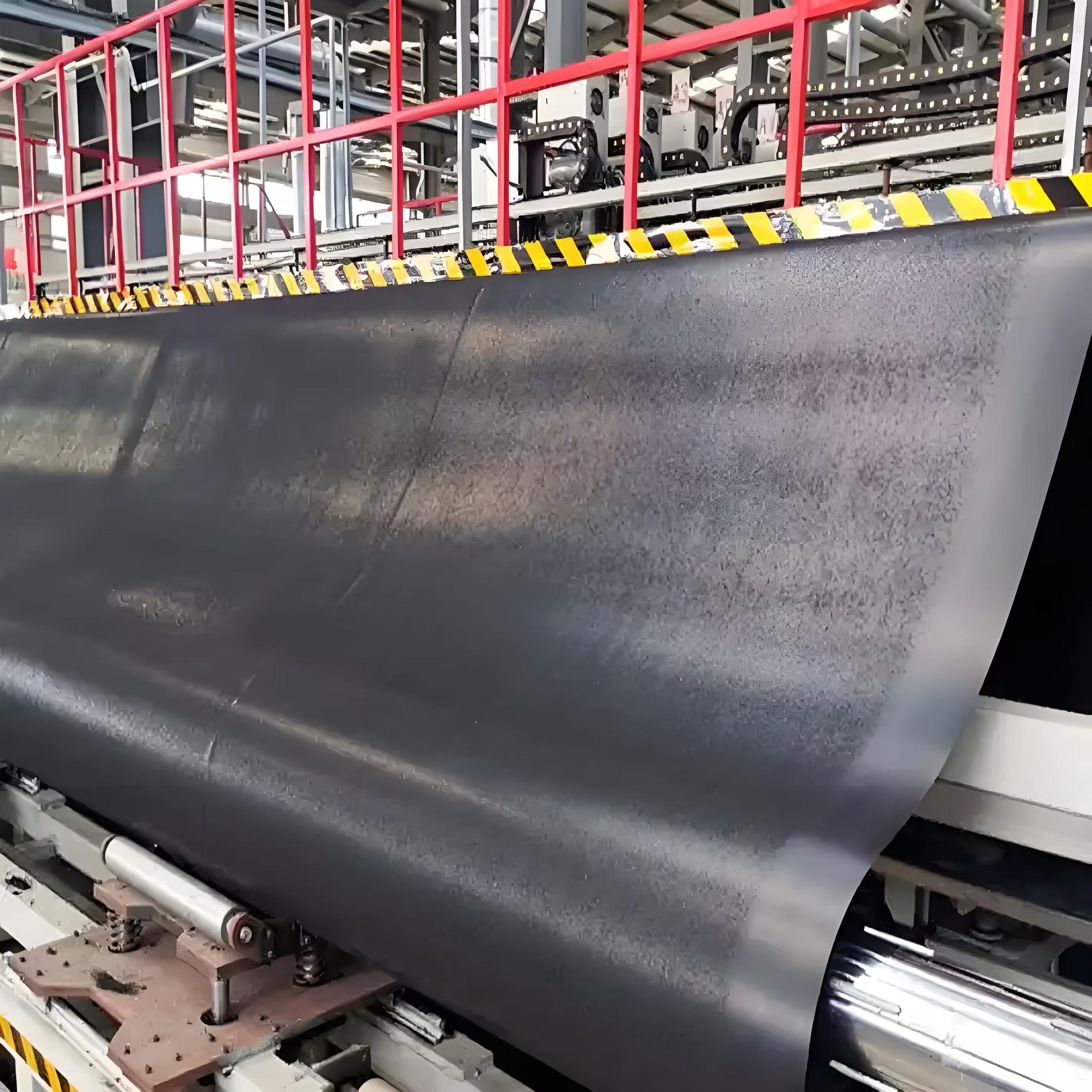

Conventional width: 6m width (customizable for 1-6 meters)

Regular length: 50 meters (customizable)

Thickness: 0.2mm-3.0mm

Color: Black, White, Blue, Green (customizable)

Keywords: plastic film, HDPE plastic film, pond lining, waterproof film, 0.5mm plastic film, 1.0mm plastic film, plastic film lining, HDPE lining, landfill lining, plastic film, shrimp pond lining, tailings pond plastic film

Performance characteristics:

1. Strong anti-seepage performance

High anti-seepage coefficient: Rough surface geomembrane has a very low permeability coefficient, usually much lower than 1.0 × 10-13cm/s, which means it can effectively prevent the infiltration of water molecules and other harmful substances, ensuring the long-term stable operation of engineering facilities.

Widely used: In hydraulic engineering, such as reservoirs, dams, canals, etc., rough surface geomembranes can effectively prevent water infiltration and erosion, improving the safety and stability of the project. Meanwhile, in environmental protection projects such as sewage treatment and landfill sites, it can also play an important role in anti-seepage.

2. Good durability and aging resistance

Anti aging ability: After special treatment, the rough geomembrane has good anti-aging, anti ultraviolet and anti decomposition ability, and can maintain the stability of its physical and chemical properties under various environmental conditions for a long time.

Long service life: Due to its excellent durability and aging resistance, the service life of rough surface geomembranes can reach 50-70 years, providing long-term and reliable anti-seepage guarantee for engineering facilities.

3. Good corrosion resistance

Chemical stability: Rough faced geomembranes have excellent chemical stability and can resist the erosion of various chemical substances, including more than 80 strong acid and alkali chemical media such as acids, alkalis, and salts. This enables it to exhibit excellent anti-seepage effects in corrosive environments such as sewage treatment and chemical reaction tanks.

4. Strong tensile strength

High strength and high elongation: Rough faced geomembranes have high tensile strength and elongation, and can maintain stable performance under large temperature and humidity changes. This characteristic enables it to be used in various complex geological conditions without fracturing or failing due to soil movement or deformation.

5. Rough surface design enhances friction

Increasing friction: The surface of rough geomembrane has rough stone patterns or column point designs, which increase friction with soil or other materials, preventing sliding or leakage. At the same time, it can also increase the area combined with the soil and improve the anti-seepage effect.

6. Convenient construction

Lightweight materials: Rough faced geomembranes are relatively lightweight, making them easy to transport and install, and reducing engineering costs.

There are various connection methods: During the construction process, rough surface geomembranes can be connected by welding or bonding, which is simple and fast to operate.

Function and purpose:

Environmental protection projects such as garbage disposal sites, sewage treatment plants, petrochemicals, metallurgy, etc;

Water conservancy projects such as reservoirs, dams, rivers, lakes, etc;

◎ Subway, tunnel, underground warehouse, etc;

Artificial lakes, scenic spots, and other landscaping projects;

The construction market and other waterproofing projects.

Landfill: High density polyethylene geomembrane is commonly used as an inner lining for landfills to prevent leachate from contaminating groundwater. Leachate contains substances that are harmful to the environment.

Ponds and lagoons: They are used as linings in decorating ponds, fish ponds, lagoons, and artificial lakes to prevent water leakage to the ground.

Reservoirs and storage tanks: They are also used as linings for reservoirs, storage tanks, and other facilities that store water, other liquids, and even gases.

Canal: High density polyethylene geomembrane is commonly used for lining canals, ditches, or other waterways to prevent soil erosion.

Mining industry: In the mining industry, they are used as linings for tailings ponds and leaching ponds to prevent pollution of the surrounding environment.

Agriculture: In agriculture, they can be used to irrigate ditches, farm ponds, and even to fill manure lagoons.

Construction: It can be used as a moisture-proof layer under concrete slabs or inside basement walls to prevent moisture from entering.

Environmental remediation: They are used in environmental remediation projects to contain pollutants or prevent their spread to neighboring areas.

Oil and gas industry: They can be used for secondary sealing of fuel storage tanks to prevent any potential leakage and pollution of the surrounding environment.

Aquaculture: In aquaculture, high-density polyethylene geomembrane is used in fish and shrimp ponds to maintain water quality and prevent diseases.

The above are just a few examples, and the use of high-density polyethylene geomembrane may vary greatly depending on the specific requirements of the project.

Construction plan specifications:

Do not drag or forcefully pull the geomembrane during transportation to avoid sharp objects from puncturing it.

1. It should extend from the bottom to the high position, without pulling too tightly, leaving a margin of 1.50% for local sinking and stretching. Considering the actual situation of this project, the slope will be laid in a top-down sequence;

2. The longitudinal joints of adjacent frames should not be on the same horizontal line and should be staggered by more than 1m from each other;

3. The longitudinal joint should be at least 1.50m away from the dam foot and bend foot, and should be set on a flat surface;

4. First, the bottom of the slope;

5. When laying the slope, the direction of the film should be basically parallel to the maximum slope line.

Technical indicators of rough HDPE geomembrane

Serial Number | Index | Test value | |||||

|

| 1.00mm

| 1.50mm | 2.00mm | 1.25mm | 2.50mm | 3.00mm |

1 | Rough height, mm | 0.25 | |||||

2 | Minimum density,g/cm' | 0.939 | |||||

3 | Tensile property |

|

|

|

|

|

|

| Yield strength (stress), N/mm | 15 | 18 | 22 | 29 | 37 | 44 |

| Fracture strength (stress), N/mm | 10 | 13 | 16 | 21 | 26 | 32 |

| Yield elongation,% | 12 | |||||

| Fracture elongation,% | 100 | |||||

4 | Right angle tear strength, N | 125 | 156 | 187 | 249 | 311 | 374 |

5 | Puncture intensity, N | 267 | 333 | 400 | 534 | 667 | 800 |

6 | Environmental stress cracking resistance (single point cut constant load tensile method), hr | 300 | |||||

7 | Carbon black |

| |||||

| Carbon black content (range),% | 2.0-3.0 | |||||

| Carbon black dispersion | Out of 10 observations, 9 should be at level 1 or 2, and no more than 1 should be at level 3. | |||||

8 | Oxidation induction time (OTT) |

| |||||

| Standard OT, min; or | 100 | |||||

| High voltage OrT, min | 400 | |||||

9 | 85 ° C oven aging (minimum average) |

| |||||

| After baking for 90 days, the retention rate of standard OTT is%; or | 55 | |||||

| After baking for 90 days, the retention of high voltage OTT % | 80 | |||||

10 | UV resistance intensity |

| |||||

| After 1600 hours of ultraviolet irradiation,the retention rate of standard OTT is%:; or | 50 | |||||

| After 1600 hours of ultraviolet irradiation, the retention rate of high-pressure OTT was%; | 50 | |||||

11 | -Low temperature impact embrittlement performance at 70 ℃ | Pass | |||||

12 | Water vapor permeability coefficient g · cmy (c ㎡. s-Pa) | ≤1.0x10-1 | |||||

13 | Dimensional stability% | ±2 | |||||

1、 Physical performance parameters

1. Density and thickness: The density of HDPE rough surface geomembrane is usually greater than 0.94g/cm ³, ensuring its excellent physical properties. In terms of thickness, it usually ranges from 0.5mm to 3.0mm according to engineering needs, meeting the anti-seepage requirements in different scenarios.

2. Specification and size: HDPE rough surface geomembrane is usually supplied in the form of rolls, with a width generally between 6 meters and 8 meters, and the length can be customized according to engineering needs. In terms of specifications and dimensions, the maximum deviation of rough HDPE geomembrane should be controlled within ± 15% to ensure accuracy during construction.

3. Rough surface height: Rough surface height is an important parameter of HDPE rough surface geomembrane, usually between 0.25mm and 0.5mm. The increase in roughness height helps to improve the shear strength and friction angle between the geomembrane and other materials, thereby enhancing the stability of the slope.

2、 Mechanical performance parameters

1. Fracture strength: The fracture strength of HDPE rough surface geomembrane is an important indicator for measuring its tensile resistance. Generally speaking, the fracture strength of rough HDPE geomembrane should be above 16N/mm to ensure that it is not easily broken under external forces.

2. Right angle tear strength: Right angle tear strength reflects the resistance of geomembranes to right angle tear forces. The right angle tear strength of rough HDPE geomembrane usually reaches 187N or above, with high tear resistance.

3. Puncture strength: Puncture strength is an important indicator for measuring the ability of geomembranes to resist sharp object punctures. The puncture strength of rough HDPE geomembrane usually reaches over 400N, effectively preventing possible puncture damage during construction.

3、 Chemical stability parameters

1. Chemical corrosion resistance: HDPE rough surface geomembrane has excellent chemical corrosion resistance and can resist the erosion of various chemical substances such as acid, alkali, salt, etc. This enables it to maintain stable performance in various complex engineering environments.

2. Anti aging performance: rough surface HDPE geomembrane is made of high-density polyethylene native resin, which has good anti-aging performance. Even under long-term exposure to natural environments such as sunlight and rain, it can maintain good physical and mechanical properties.

4、 Environmental adaptability parameters

1. Temperature adaptability: HDPE rough surface geomembrane has excellent temperature adaptability and can maintain stable performance in the temperature range of -40 ℃ to 60 ℃. This enables it to work reliably under various climatic conditions.

2. Weather resistance: Rough HDPE geomembrane has good weather resistance and can resist the erosion of natural factors such as ultraviolet radiation and ozone. Even under long-term exposure to outdoor environments, it can maintain good appearance and performance.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.