PRODUCT DETAILS

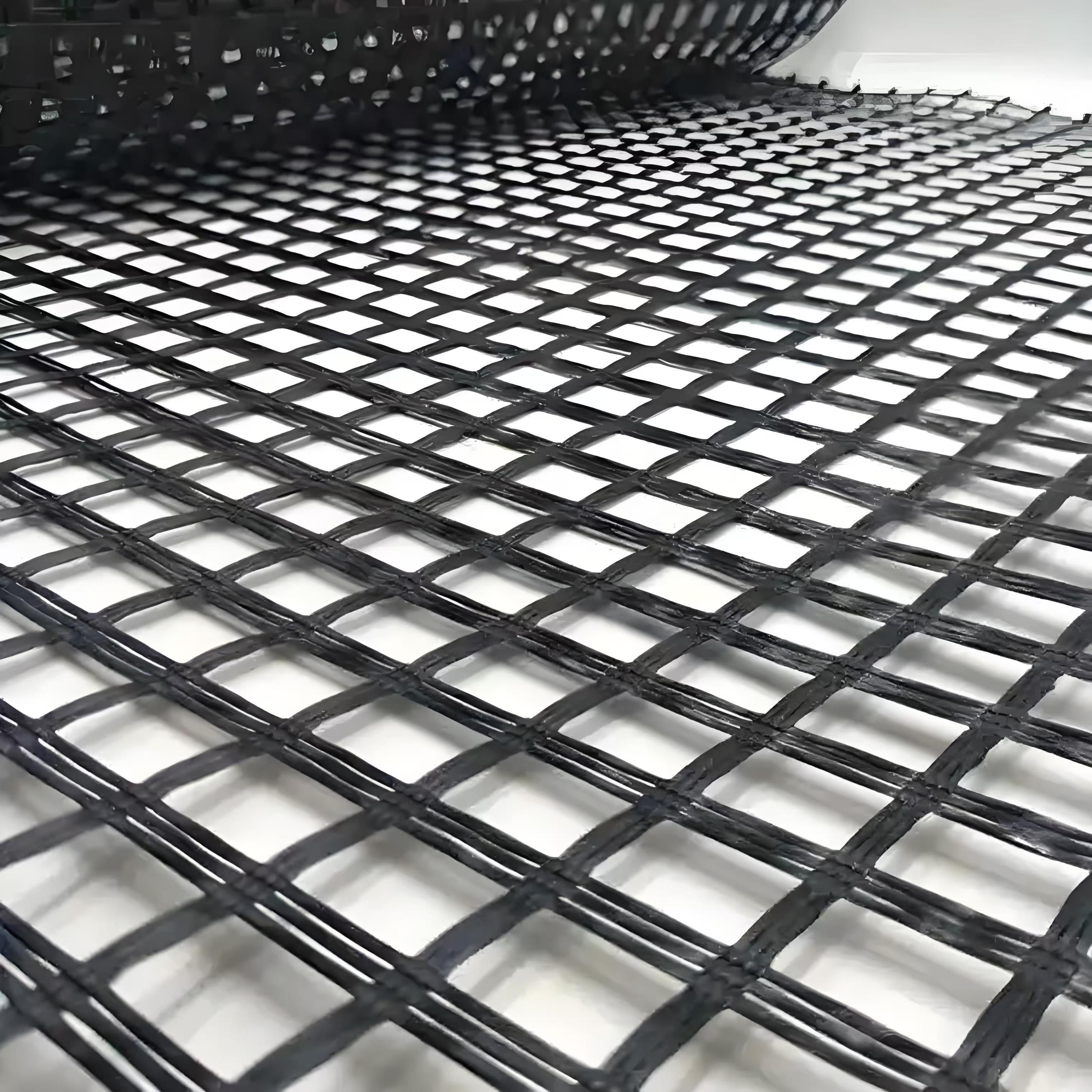

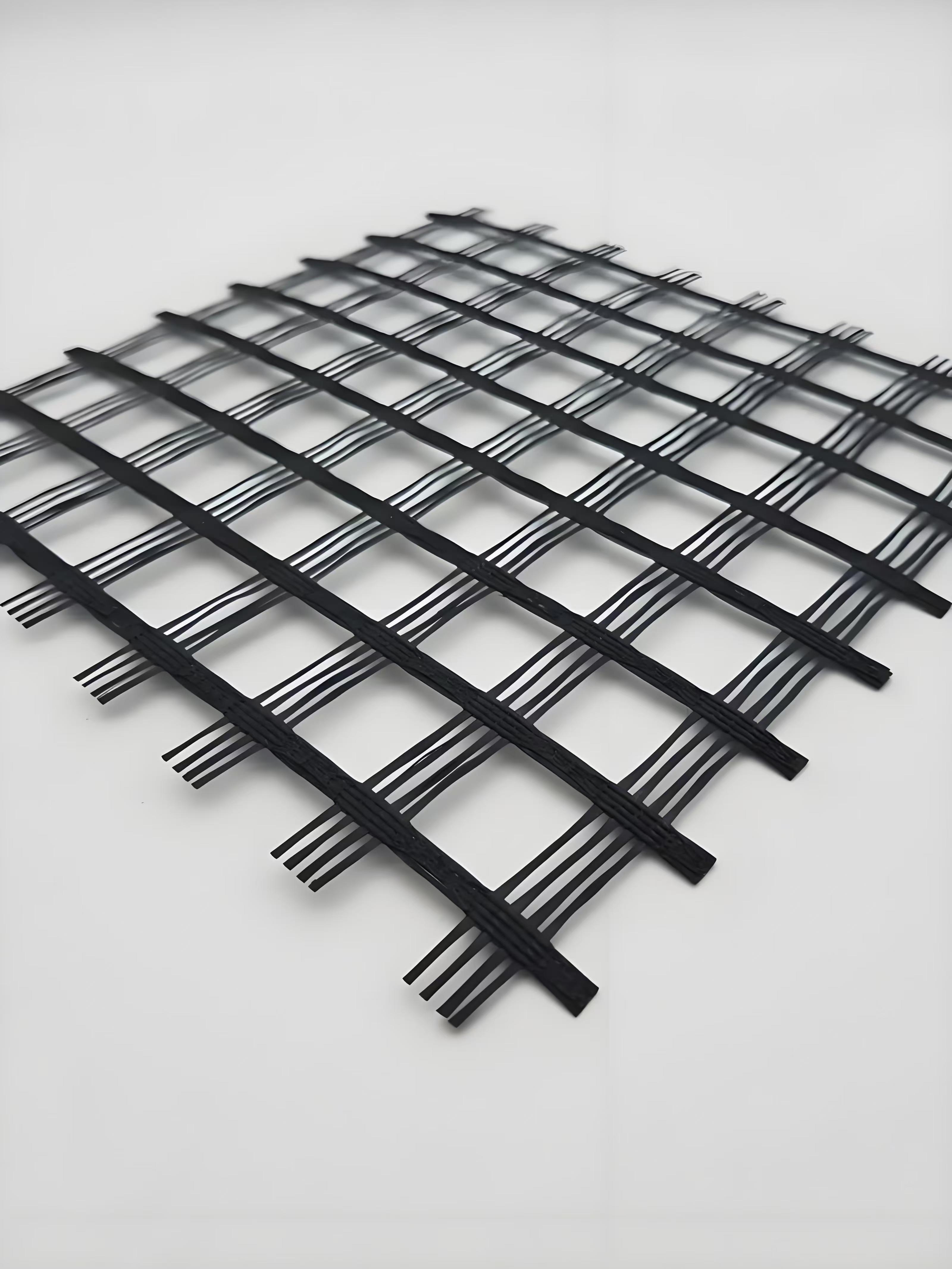

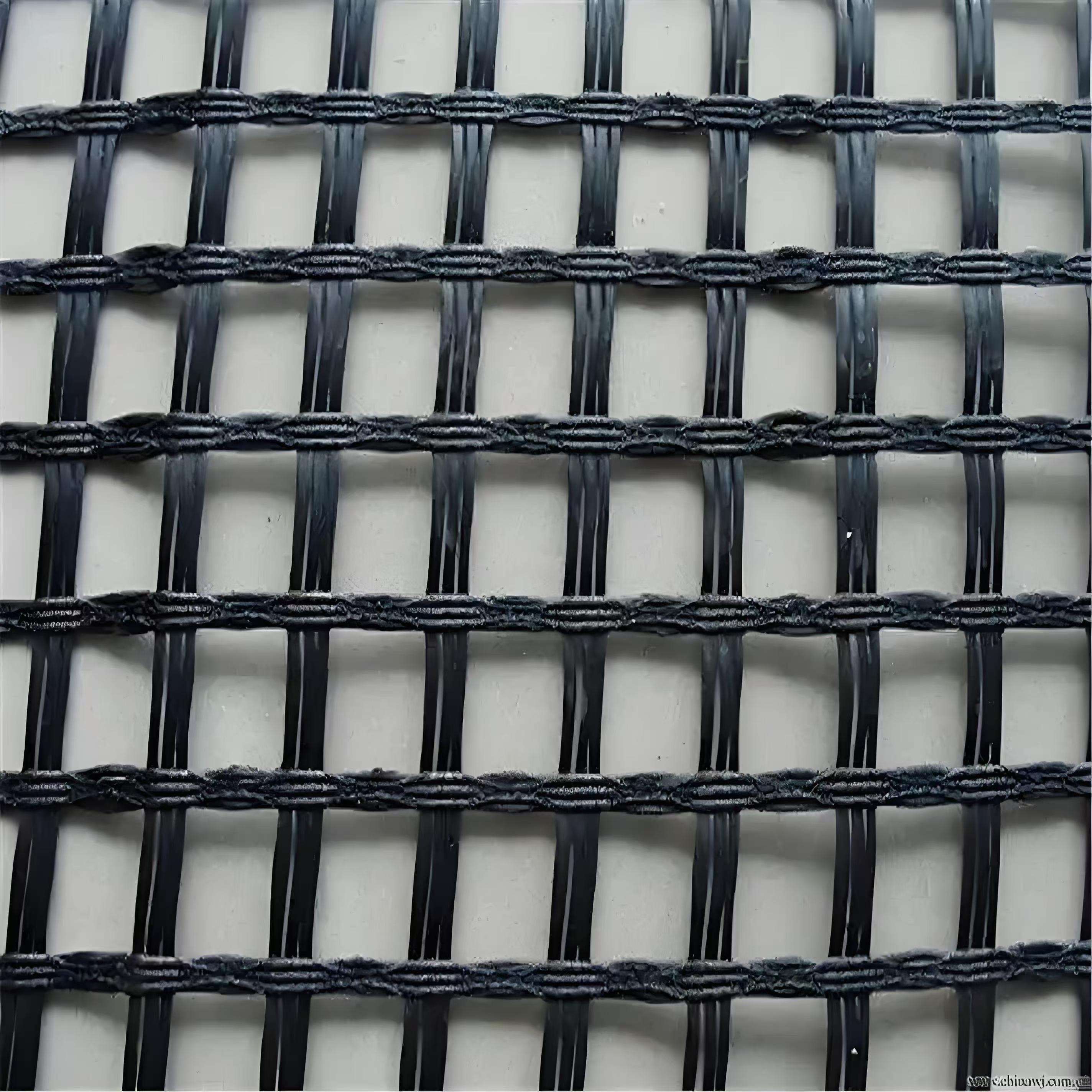

Fiberglass grating is a composite material made by processing raw materials such as fiberglass and polyester resin through special processes. Its main components include glass fiber and unsaturated polyester resin. The production process of fiberglass grating includes steps such as raw material preparation, fiberglass weaving, resin impregnation, hot pressing, cooling and cutting, which require strict control of various parameters to ensure product quality.

Width size

The width range of fiberglass grating is generally between 20cm and 120cm. The specific width can be determined according to the usage scenario. For example, in industrial production, a wider grille may be required to carry a large number of items, while in the transportation field, a narrower grille is needed to ensure the safety of vehicle travel.

In addition, the conventional width of fiberglass geogrids is generally 4 meters and 6 meters, and special sizes can also be customized. This type of grille is usually laid in the direction of the road and is suitable for reinforcing materials on new and old road surfaces, with a wide range of applications.

Characteristic

Fiberglass grating has the following main characteristics:

High strength and corrosion resistance: Glass fiber grating is made of high-strength glass fiber and polyester resin materials, with high tensile and compressive strength, and can withstand large loads. In addition, it has good corrosion resistance and can be used for a long time in harsh environments.

Lightweight and easy to install: Fiberglass grating is lightweight, easy to handle and install, and can significantly improve construction efficiency.

Durability: Fiberglass grilles have a long service life, are not easily affected by external environments, and have good durability.

Thermal stability and high temperature resistance: The melting temperature of glass fiber is above 1000 ℃, ensuring that the glass fiber grid can maintain stable performance in high temperature environments.

Compatibility with asphalt mixture: After special post-treatment, fiberglass grating has high compatibility with asphalt mixture and can be firmly combined to improve the overall performance of asphalt pavement.

Physical and chemical stability: Fiberglass grating can resist various physical wear and chemical erosion, as well as biological erosion and climate change, ensuring its performance is not affected.

No long-term creep: Under long-term loads, fiberglass grids can maintain stable performance and are not prone to creep or relaxation, thereby ensuring the long-term stability of the project.

Environmental friendliness: Fiberglass grilles do not produce harmful substances during production and use, making them environmentally friendly.

Anti aging: glass fiber grille has excellent anti-aging performance, long service life, and reduced maintenance and replacement costs.

Construction convenience: Fiberglass grating is lightweight, easy to cut and lay, which can greatly simplify the construction process and improve construction efficiency.

application area

Its main application areas include roadbed and pavement reinforcement for highways, railways, and airports, foundation reinforcement for large parking lots and dock cargo yards, slope protection for railways and highways, culvert reinforcement, mine and tunnel reinforcement, reinforcement of old asphalt concrete pavements, and reinforcement of composite pavements for cement concrete pavement reconstruction.

Reinforcement of roadbeds and pavements in highways, railways, and airports: Fiberglass grids can improve the bearing capacity of roadbeds and pavements, reduce the formation of cracks and ruts, and extend their service life.

Ground reinforcement for large parking lots and dock cargo yards: In permanent load-bearing foundations, fiberglass grids can enhance the stability and bearing capacity of the foundation, preventing settlement and deformation.

Slope protection for railways and highways: used for slope protection, preventing soil erosion, and improving slope stability.

Culvert reinforcement: Enhance the structure in the culvert to improve its load-bearing capacity and durability.

Reinforcement of mines and tunnels: Used in mines and tunnels to improve structural stability and safety.

Reinforcement and strengthening of old asphalt concrete pavement: used for the renovation of old pavement, improving the overall integrity and bearing capacity of the pavement, reducing the formation of cracks and ruts.

Cement concrete pavement reconstruction composite pavement: In the reconstruction of cement concrete pavement, fiberglass grating can enhance the shear resistance and overall integrity of the pavement.

Indicator parameters

Raw material: The raw material for glass fiber grating is glass fiber, and its alkali metal oxide content should be ≤ 0.8%.

Ultimate tensile strength: Ultimate tensile strength is a measure of the ability of grid materials to withstand tensile forces, usually requiring ≥ 50KN/m.

Ultimate elongation: The ultimate elongation represents the maximum deformation that a material can withstand during the stretching process, usually requiring ≤ 4%.

Fracture strength after thermal aging: After thermal aging treatment, the fracture strength of the grille should not be less than 90% of the original strength.

Fracture strength and elongation at break: Different types of glass fiber grilles have different fracture strength and elongation at break. For example, the longitudinal and latitudinal fracture strength of the GG2525 grille is ≥ 25 kN/m, and the elongation at break is ≤ 4%; The longitudinal and latitudinal fracture strength of the GG3030 grille is ≥ 30 kN/m, and the elongation at break is ≤ 4%.

Physical and chemical stability: Glass fiber grating has excellent physical and chemical stability, which can resist various physical wear and chemical erosion, as well as biological erosion and climate change.

Application areas: Fiberglass grating is widely used in the reinforcement of asphalt pavement, cement pavement and roadbed, as well as railway roadbed, embankment slope protection, airport runway, sand control and other engineering projects.

These indicator parameters collectively determine the performance and application range of fiberglass grilles, ensuring their effectiveness and durability in various engineering applications.

Construction method of fiberglass grating:

Before laying the fiberglass grid, ensure that there are no defects on the appearance, and it must be tightly attached to the surface of the underlying layer. It must be kept flat, wrinkle free, fracture free, and undamaged. The laying time of fiberglass grating should be between 10am and 3pm on sunny days, with both ends tensioned and fixed, and a folding length of about 1m left. Fiberglass grating is generally fixed with 30x0.3 white iron sheet and 2-inch steel nails. The steel nails cannot be directly nailed to the fiberglass grating. The fixing spacing along the longitudinal direction of the fiberglass grating is 1m, and the transverse direction of the fiberglass grating is 0.5m, arranged in a plum blossom shape. The overlap distance of longitudinal and transverse joints shall not be less than 20cm and 15cm respectively. When conducting longitudinal overlap, it is necessary to follow the direction of asphalt paving and place the previous one on top of the next. Fiberglass grating should not be exposed to rain or direct sunlight, and the exposure time should not exceed 48 hours. The lower sealing layer construction should be carried out immediately. When laying fiberglass grids, it is necessary to completely block traffic and prohibit construction vehicles from braking or turning on the road surface. After the construction of the fiberglass grid is completed, immediately spray the adhesive layer asphalt oil. After the application of the adhesive layer oil, the stone chips or melon and rice stones should be evenly spread immediately. After the stone chips are spread, a lightweight rubber roller should be used immediately for moderate compaction

The future development trend of fiberglass grating

Research and development of environmentally friendly materials: With the increasing awareness of environmental protection, future research and development will pay more attention to the application of environmentally friendly materials to reduce pollution to the environment.

Development of high-performance materials: Emphasis is placed on improving the performance of materials, such as enhancing tensile strength, improving corrosion resistance, etc., to meet higher requirements for engineering applications.

The application of intelligent technology: With the development of intelligent technology, production and application will pay more attention to intelligent technology, such as automated production lines, intelligent detection, etc., to improve production efficiency and product quality.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.