PRODUCT DETAILS

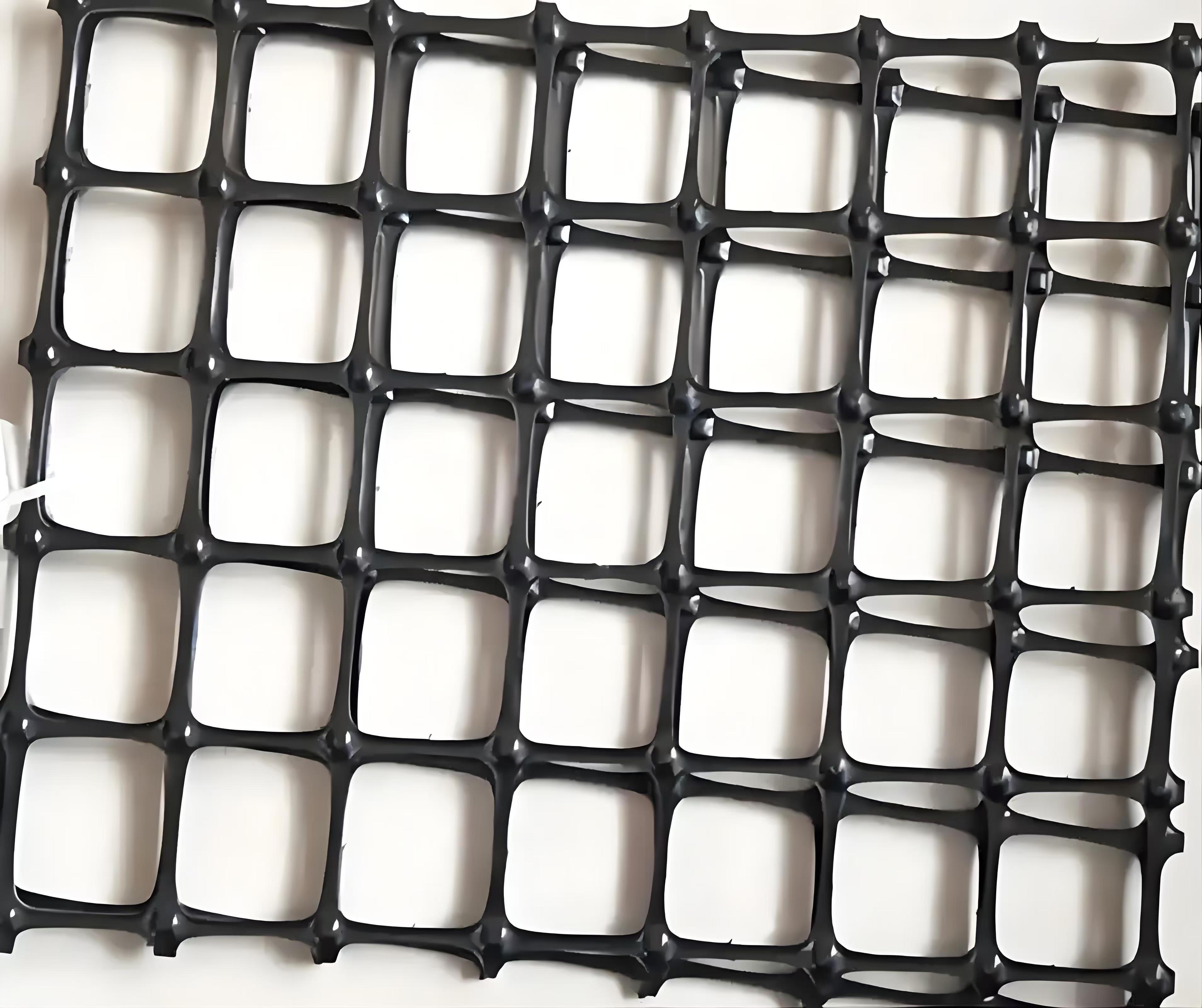

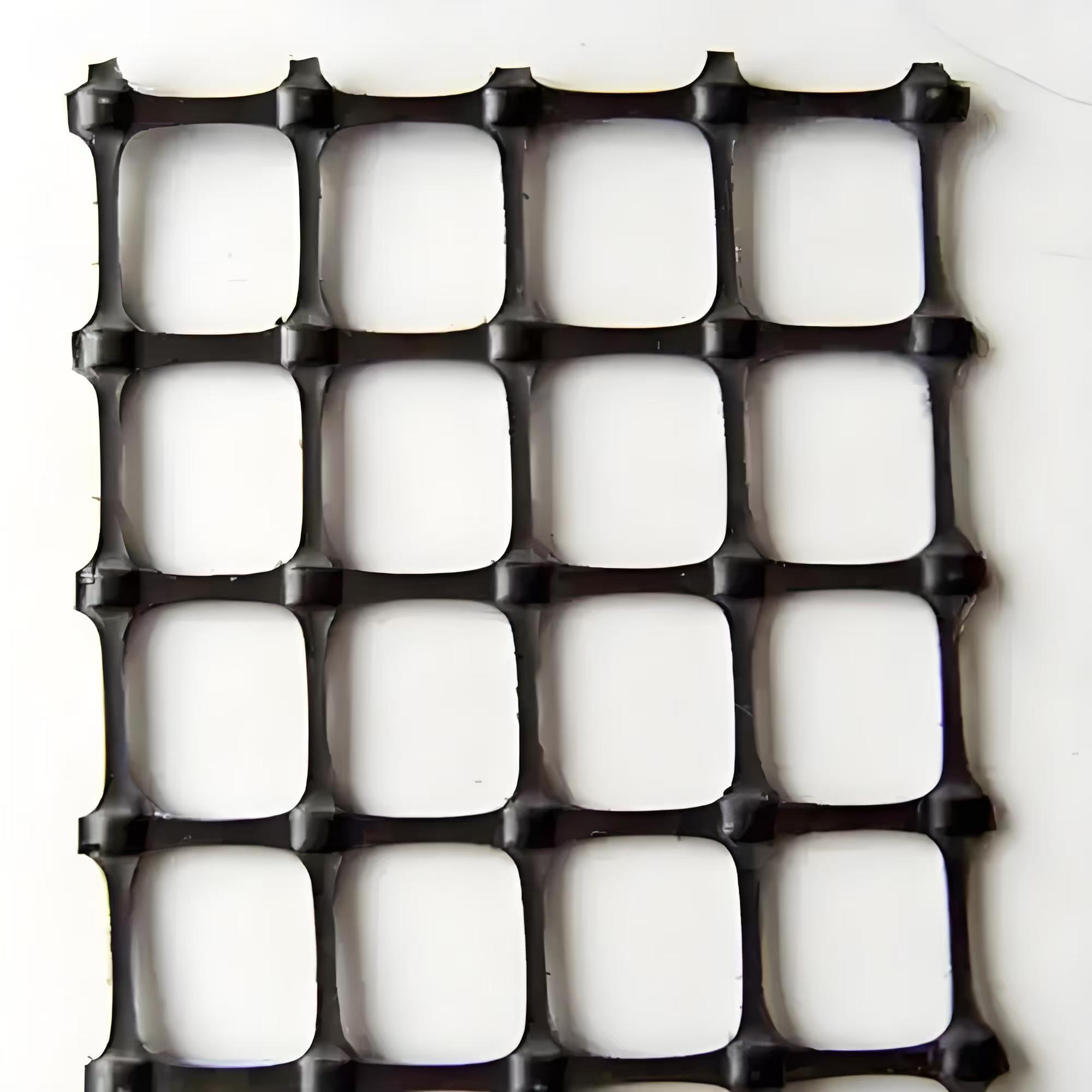

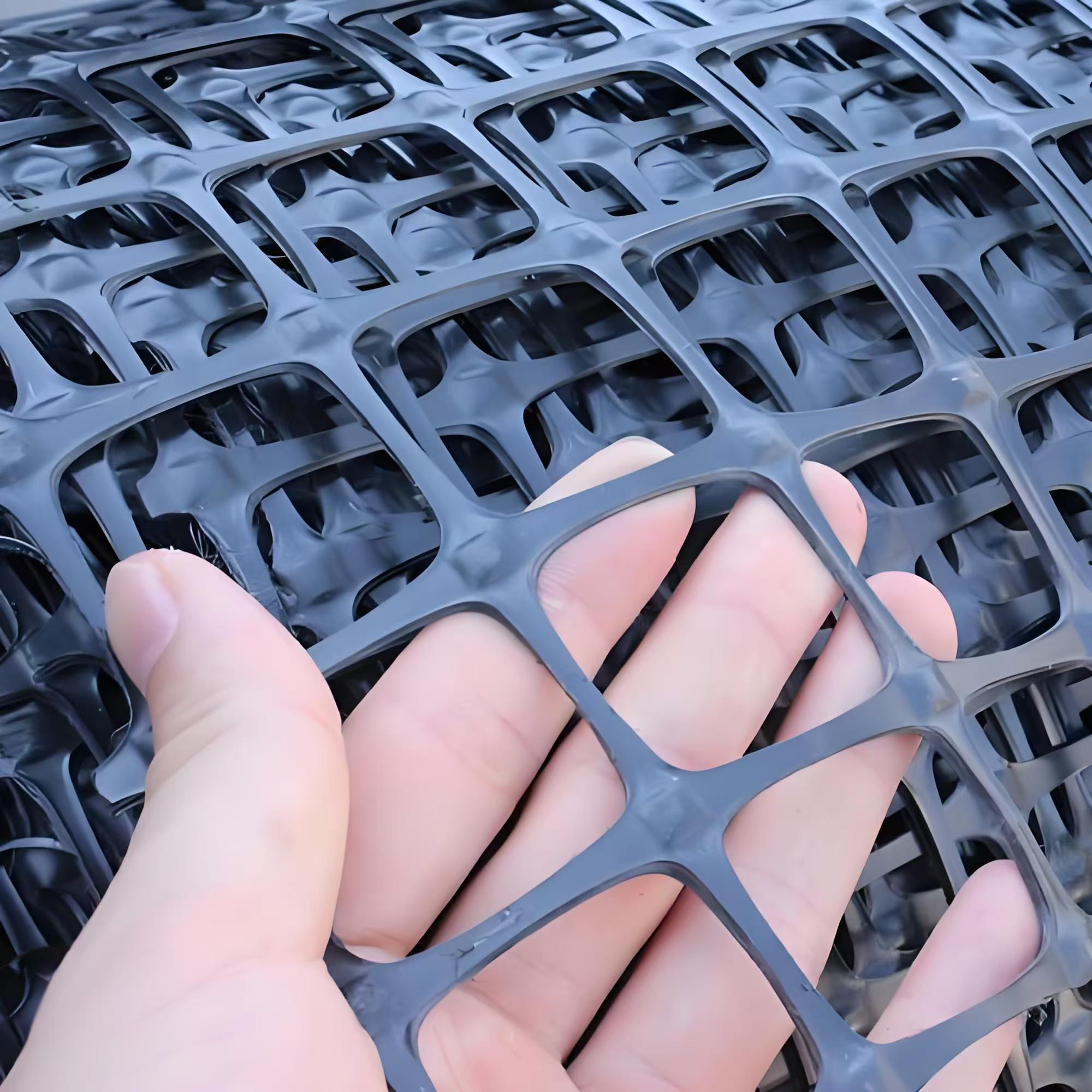

Plastic grating panels are mainly made of plastic materials such as polypropylene (PP) and polyethylene (PE). These plastic raw materials undergo specific manufacturing processes such as melting, extrusion, stretching, etc. to form grid plates with a mesh structure. Plastic grating panels have excellent physical and mechanical properties, chemical stability, and UV resistance, making them suitable for various environments and application scenarios.

Width size

The width range of plastic grille materials is usually between 1 meter and 6 meters. Specifically, the width of plastic grilles can come in the following specifications: 1 meter, 2 meters, 3 meters, 4 meters, 5 meters, and 6 meters. (Specific dimensions can be customized according to on-site conditions)

Plastic grille materials have the following characteristics:

Lightweight: The plastic grille material is lightweight, much lighter than traditional metal materials, making installation and transportation relatively convenient.

Corrosion resistance: The plastic grille is made of corrosion-resistant materials, which can effectively prevent chemical erosion.

Anti slip: The surface of the plastic grille has anti slip patterns, combined with its own anti slip performance, which can greatly reduce the risk of use in wet and slippery conditions.

Thermal insulation: The plastic grille has good heat dissipation performance and will not deform or crack even when used in high temperature environments.

Easy to install: The plastic grille is easy to install and does not require special treatment. It can be assembled using some simple overlapping methods.

Low maintenance cost: The maintenance cost of plastic grilles is very low, only requiring simple cleaning and maintenance.

Environmental Protection: Plastic grille materials are environmentally friendly, harmless to human health and the environment, and can be reused, with significant environmental protection effects.

Application scenarios include:

Plastic grille materials are widely used in various fields, mainly including the following aspects:

Wastewater treatment: Plastic grilles are used in wastewater treatment for solid-liquid separation, inlet regulation, and grille tanks. They have good corrosion resistance and can effectively reduce maintenance costs.

Road construction: Plastic grilles are used as anti slip and drainage materials for sidewalks, bridges, tunnels, and other places in road construction. They can also be used for bridge deck paving to increase the load-bearing capacity of bridges.

Landscape greening: Plastic grilles are used as edge fences for lawns, flower beds, pools, etc. They are beautiful and have good drainage performance, ensuring plant growth and water cleanliness.

Embankment and roadbed reinforcement: Plastic grating is suitable for various embankment and roadbed reinforcement, enhancing roadbed stability, extending service life, and is suitable for permanent bearing foundation reinforcement of large airports, parking lots, dock cargo yards, etc.

Landfill site: Plastic grates are used for garbage separation and stacking in landfills, effectively solving problems such as uneven settlement of foundations and emissions of derived gases, and improving the storage capacity of landfills.

Ships and docks: Plastic grilles are also used in the construction of marine engineering such as ships and docks, with good corrosion resistance and lightweight characteristics, suitable for various harsh environments.

The advantages of plastic grille materials include:

Corrosion resistance: Plastic grilles have good corrosion resistance and are suitable for various harsh environments.

Lightweight: The plastic grille material is lightweight and easy to transport and install.

Aesthetic: In landscaping, plastic grilles are not only practical but also have a beautiful appearance.

Low maintenance cost: Compared to traditional metal grilles, plastic grilles have lower maintenance costs and longer service life.

Indicator parameters

The main material parameters of plastic grilles include tensile strength, elongation, and creep conversion coefficient.

Tensile strength and elongation

Tensile strength: The ability of plastic grilles to resist fracture during the stretching process. The specific values may vary depending on the specifications. For example, the plastic grille of TGDG80 specification has a tensile strength of 21.0 kN/m at 2% elongation and 40.0 kN/m at 5% elongation.

Elongation: The ability of a grille to deform during the stretching process. The nominal elongation rate usually does not exceed 11.5%.

Creep conversion coefficient

Creep conversion coefficient RFcr: used to evaluate the stability of materials under long-term loading. Its value should be less than or equal to 2.5.

Other material characteristics

Material type: Plastic grilles are usually made of high-density polyethylene (HDPE) or polypropylene (PP), and are formed into a flat three-dimensional triangular mesh structure through processes such as extrusion, punching, and stretching.

Application scenarios: Plastic grilles are widely used in fields such as highways, railways, water conservancy, and environmental protection to enhance soil stability and bearing capacity.

Installation and maintenance precautions

Installation method: The plastic grille should be laid flat on the roadbed, tightened around it to ensure a tight fit with the roadbed, and reinforced with U-shaped iron nails or bamboo nails.

Maintenance: After the installation is completed, it should be buried in a timely manner to avoid direct sunlight exposure. If necessary, a 5cm thick soil layer should be laid on the gravel layer to protect the grid.

These indicators and parameters are crucial for ensuring the performance and stability of plastic grilles during use.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.