PRODUCT DETAILS

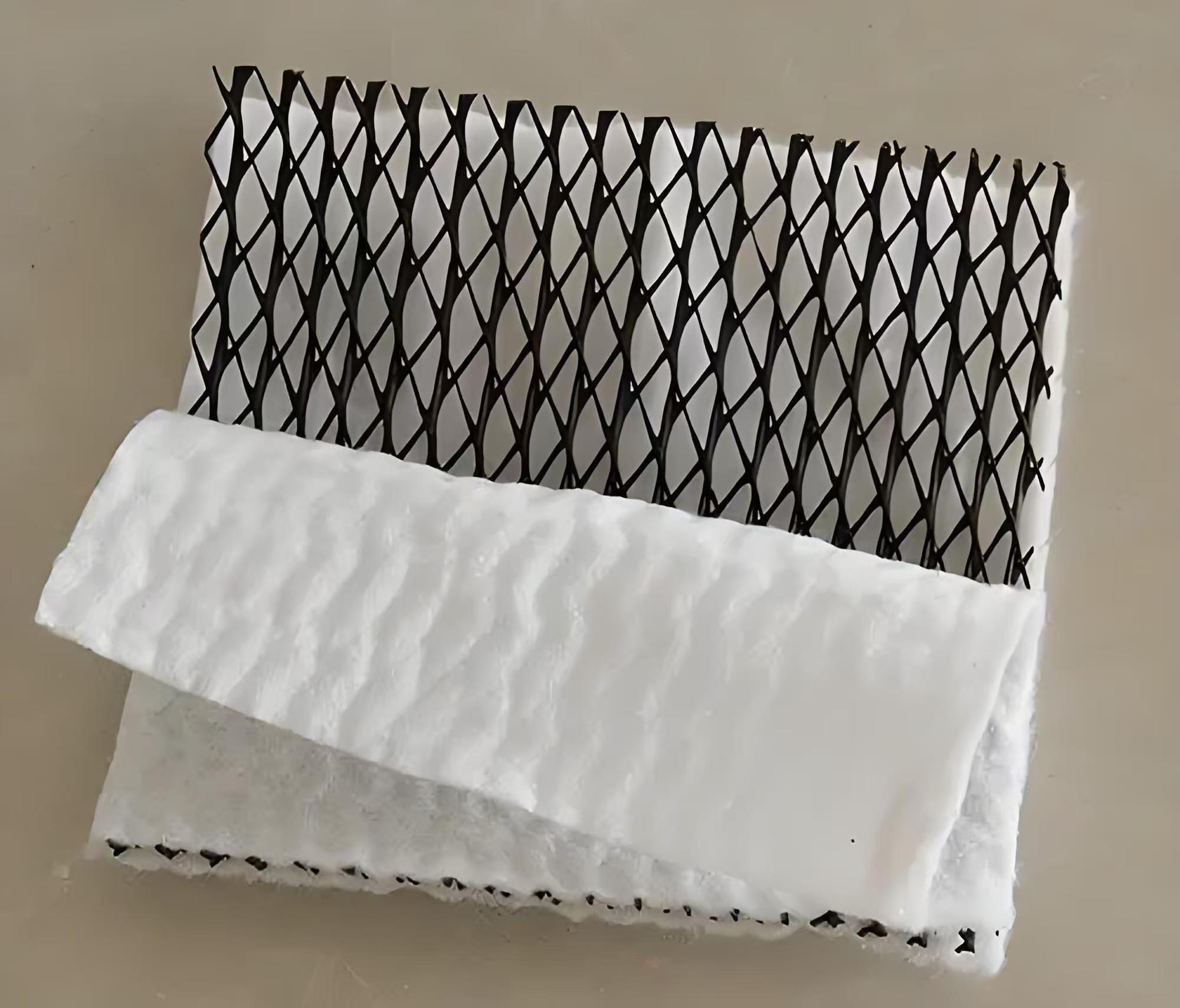

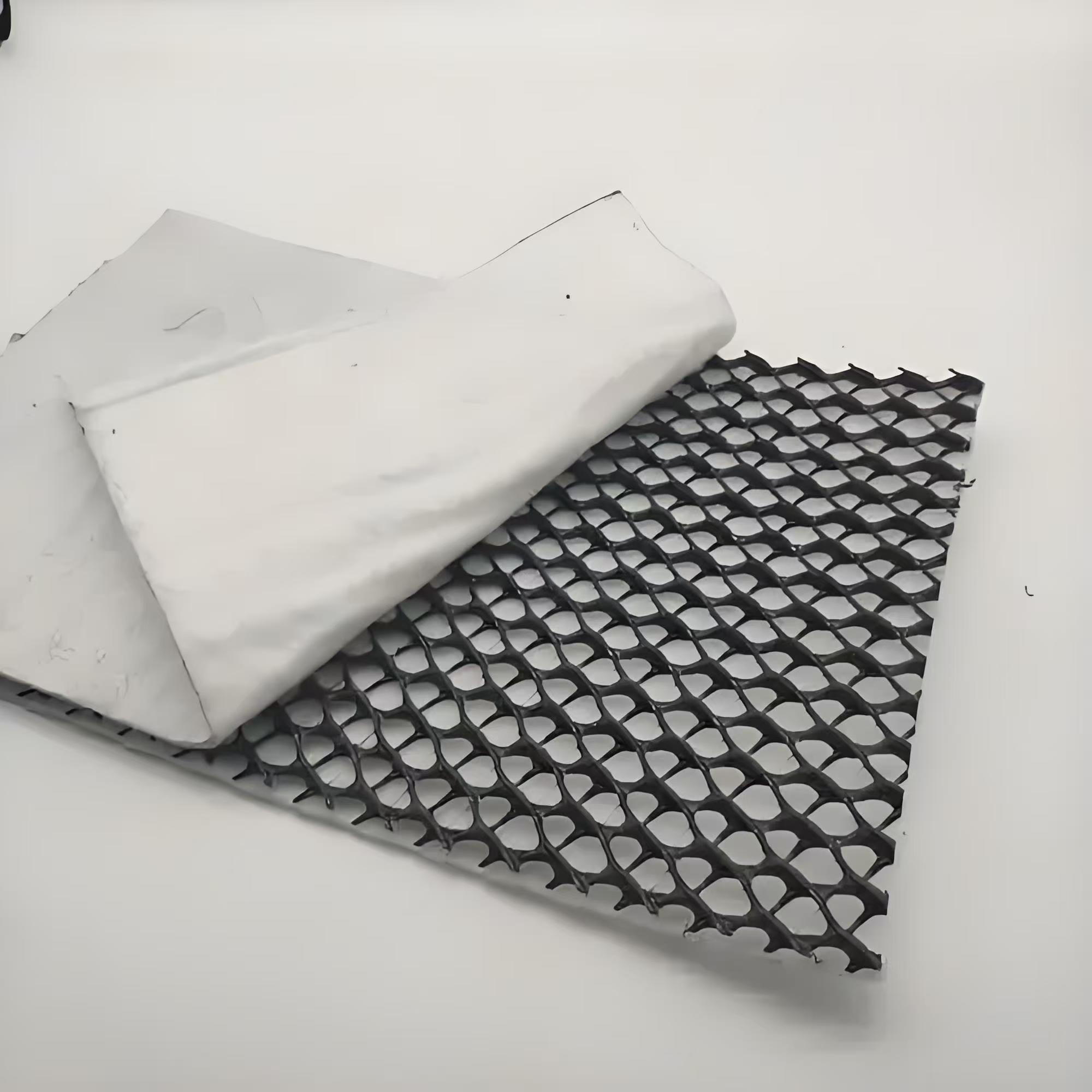

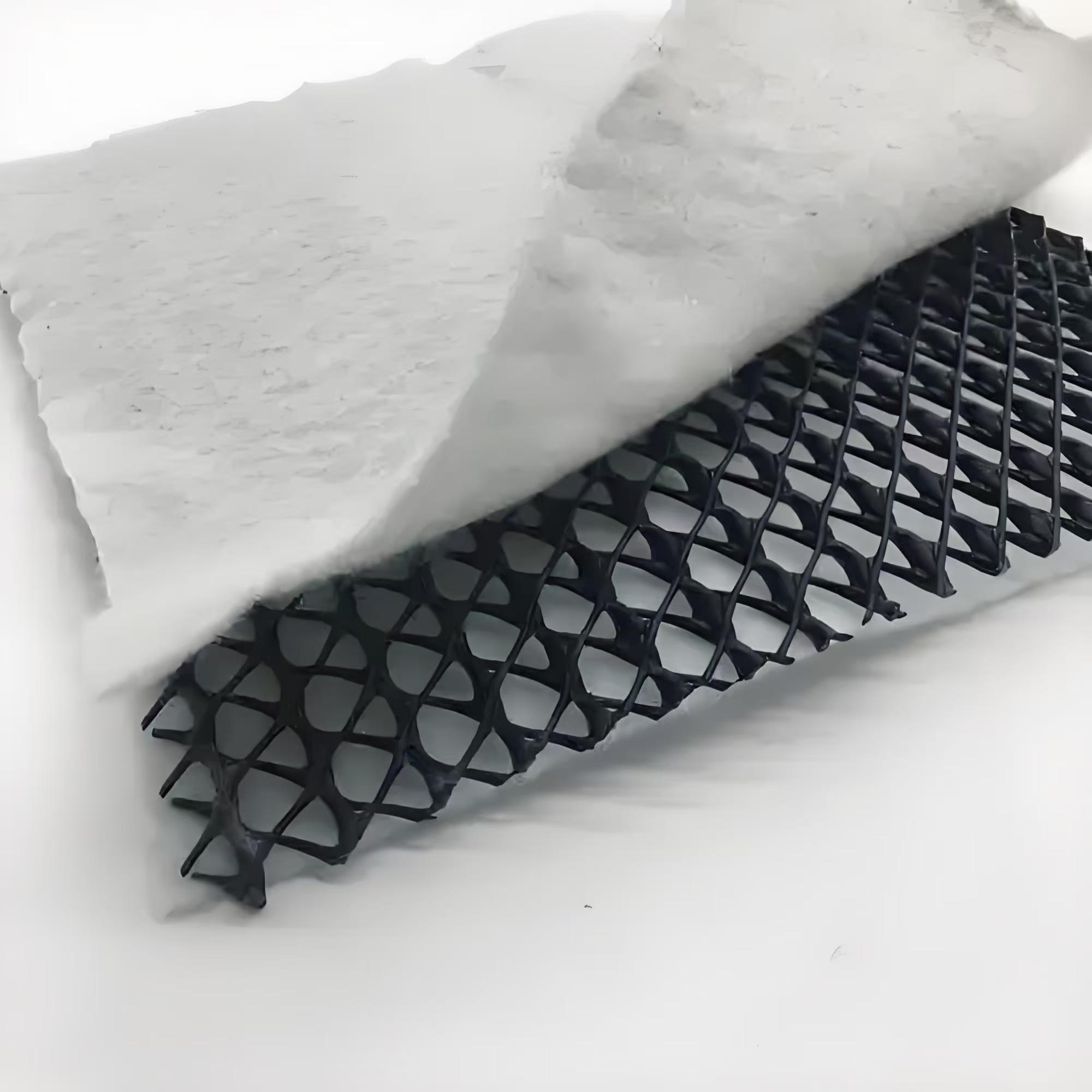

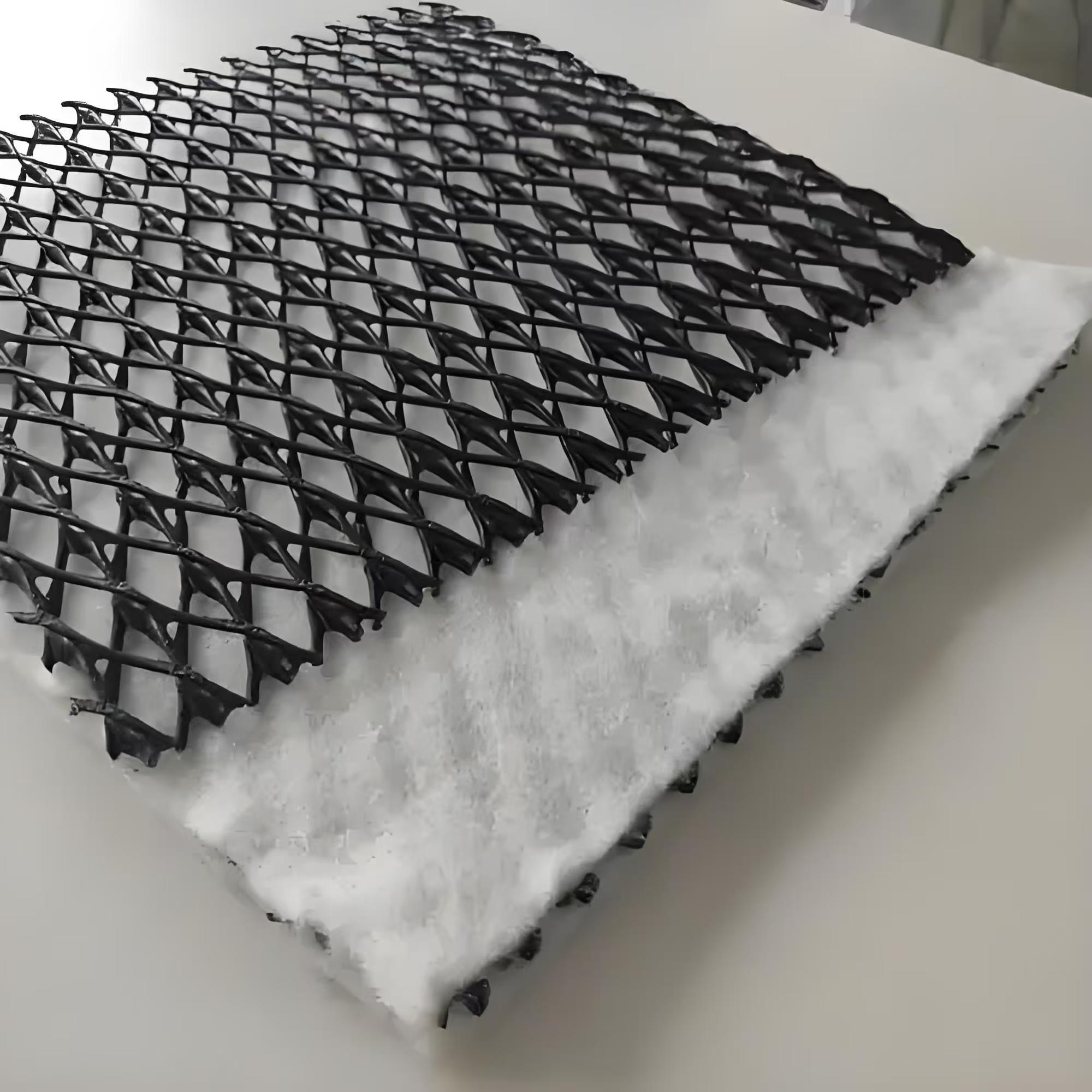

Composite drainage network is a new type of geotechnical material for drainage, mainly made of high-density polyethylene (HDPE) processed by special extrusion molding technology, with a three-layer special structure. The middle reinforcement has high rigidity and is arranged longitudinally to form a drainage channel. The cross arranged reinforcement forms a support to prevent the geotextile from being embedded in the drainage channel. Even under high loads, it can maintain high drainage performance. The main component of the composite drainage network is high-density polyethylene (HDPE), which is processed through a special extrusion molding process.

Its structural features include:

Middle reinforcement: high rigidity, arranged longitudinally, forming a drainage channel.

Cross reinforcement bars above and below: form support to prevent geotextile from being embedded in drainage channels.

Double sided adhesive permeable geotextile: with comprehensive performance of "filtration drainage breathability protection"

Width size

The width size of a composite drainage network is usually 2-4 meters. The width of traditional 3D composite drainage networks is generally 3 meters, while the latest products can reach a width of 4 meters. In addition, the roll length of composite drainage networks is usually 20 or 30 meters.

Composite drainage network is a drainage material composed of polyester filament geotextile and HDPE material drainage network core composite. Its parameters and specifications are as follows:

Parameter

Thickness: The thickness of composite drainage networks usually comes in specifications such as 4mm, 5mm, 6mm, 7mm, 8mm, etc.

Mass per unit area: The mass per unit area of the upper and lower layers is usually 120 grams, 150 grams, or 200 grams.

Permeability: At a load of 720kPa and a gradient of 2%, the permeability can reach 2500m/d and the flow rate is 13pm/m.

Creep test: After withstanding a load of 1200kPa for 10000 hours, retain more than 60% of the thickness.

Tensile strength: The tensile strength of the mesh core shall not be less than 36.5kN/m.

Melt index: The melt index is 1.0 g/10min.

Performance characteristics

Strong drainage performance: The drainage performance of the composite drainage network is equivalent to the drainage effect of one meter thick gravel, which can efficiently discharge water.

High tensile strength: Its structure can withstand high tensile forces and has high tensile strength.

Long term stability: It can reduce the probability of geotextile embedding into the mesh core and maintain long-term stable drainage performance.

Capable of withstanding high-pressure loads: able to withstand compression loads of approximately 3000 Ka, suitable for various high-pressure environments.

Corrosion and acid alkali resistance: It has good corrosion and acid alkali resistance, and a long service life.

Convenient construction: Simple construction can shorten the construction period and reduce costs.

.

Widely used in the following fields:

Roadbed construction: used for highway subgrade and railway drainage.

Landfill site: Drainage of garbage landfill site.

Garage roof: Drainage of garage roof.

Underground structure: underground structure drainage.

Wall surface of retaining wall: Drainage of retaining wall surface.

Garden and Sports Field: Garden and Sports Field Drainage

Roadbed enhancement: Enhance the drainage performance of the roadbed and extend the service life of the road.

Slope protection: used for drainage of slopes to prevent soil erosion.

Bridge pier reinforcement: Enhance the stability of the bridge pier to prevent water damage.

Coastal slope protection: used for protecting the coastline and preventing wave erosion.

Reinforcement of Reservoir Bottom: Reinforce the bottom of the reservoir to improve its safety and stability. Soft foundation treatment: used to treat soft soil foundation, improve the bearing capacity and stability of the foundation.

Composite drainage networks are widely used in drainage projects such as railways, highways, tunnels, municipal engineering, reservoirs, and slope protection, with significant effects. In addition, it is also used for drainage in landfills, roadbeds, and tunnel walls, which can replace traditional sand and gravel layers.

Laying steps

Cleaning the base layer: Before laying the composite drainage network, the foundation must be cleaned and the surface must be kept dry.

2. Determine the location of the drainage network: According to the design requirements, determine the location and shape of the drainage network, and mark it on the basis.

3. Laying drainage network: Lay the composite drainage network flat on the foundation to ensure a smooth and wrinkle free surface. If necessary, you can use a rubber mallet to gently tap it to tightly bond it with the foundation.

4. Connect the drainage pipe: According to the design requirements, connect the drainage pipe to the composite drainage network. Ensure that the connection is firm and leak proof.

5. Sand filling: Fill an appropriate amount of sand at the connection between the composite drainage network and the drainage pipe to protect the drainage network and connection from damage.

6. Backfilling soil: After filling sand, backfill an appropriate amount of soil and compact it. When backfilling soil, care should be taken not to damage the composite drainage network.

7. Compaction: Compact the backfill soil to ensure a tight connection between the composite drainage network and the soil.

8. Acceptance: After the installation is completed, acceptance shall be carried out. Check whether the laying of the composite drainage network meets the design requirements, whether the connections are firm, and whether the drainage is unobstructed. If any problems are found, they should be dealt with promptly.

Connection method

Seam and overlap of three-dimensional composite drainage network:

Adjust the direction of geosynthetic materials so that the length direction of the material roll is perpendicular to the road.

The composite geotextile drainage network must be terminated, and the geotextile on adjacent geotextile cores should be overlapped along the material roll.

Connect the geotextile cores of adjacent geotextile rolls with white or yellow plastic buckles or polymer ties to connect the material rolls. Connect with zip ties every 1 meter along the length of the material roll.

The direction of the overlapped geotextile should be consistent with the direction of the filling material stacking. If the geotextile material is laid between the foundation/base layer and the sub base layer, continuous wedge welding, flat head welding or stitching should be carried out to fix the overlapping geotextile upper layer. If suturing, it is recommended to use flat head sewing method or general sewing method to achieve the minimum requirement for stitch length.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.