PRODUCT DETAILS

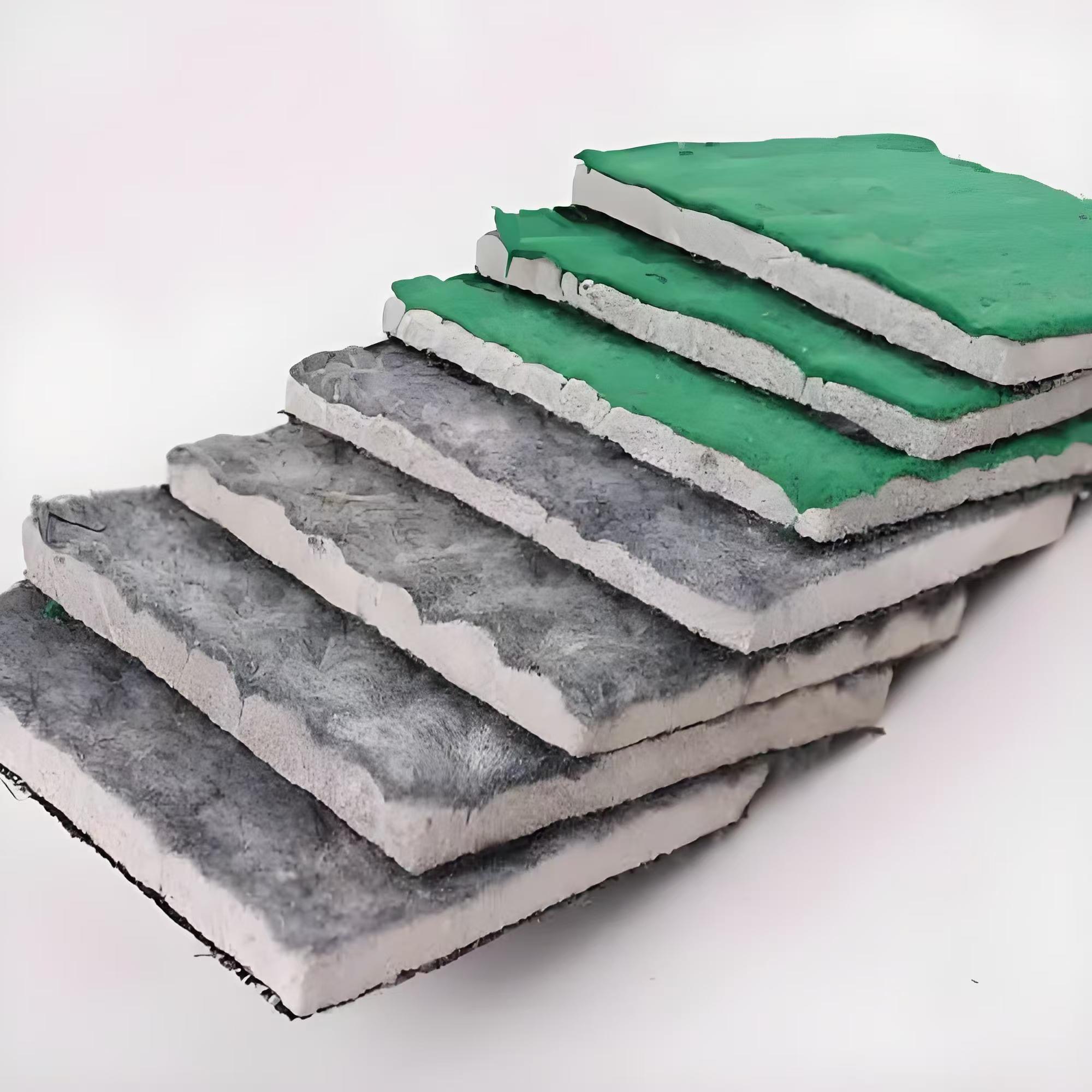

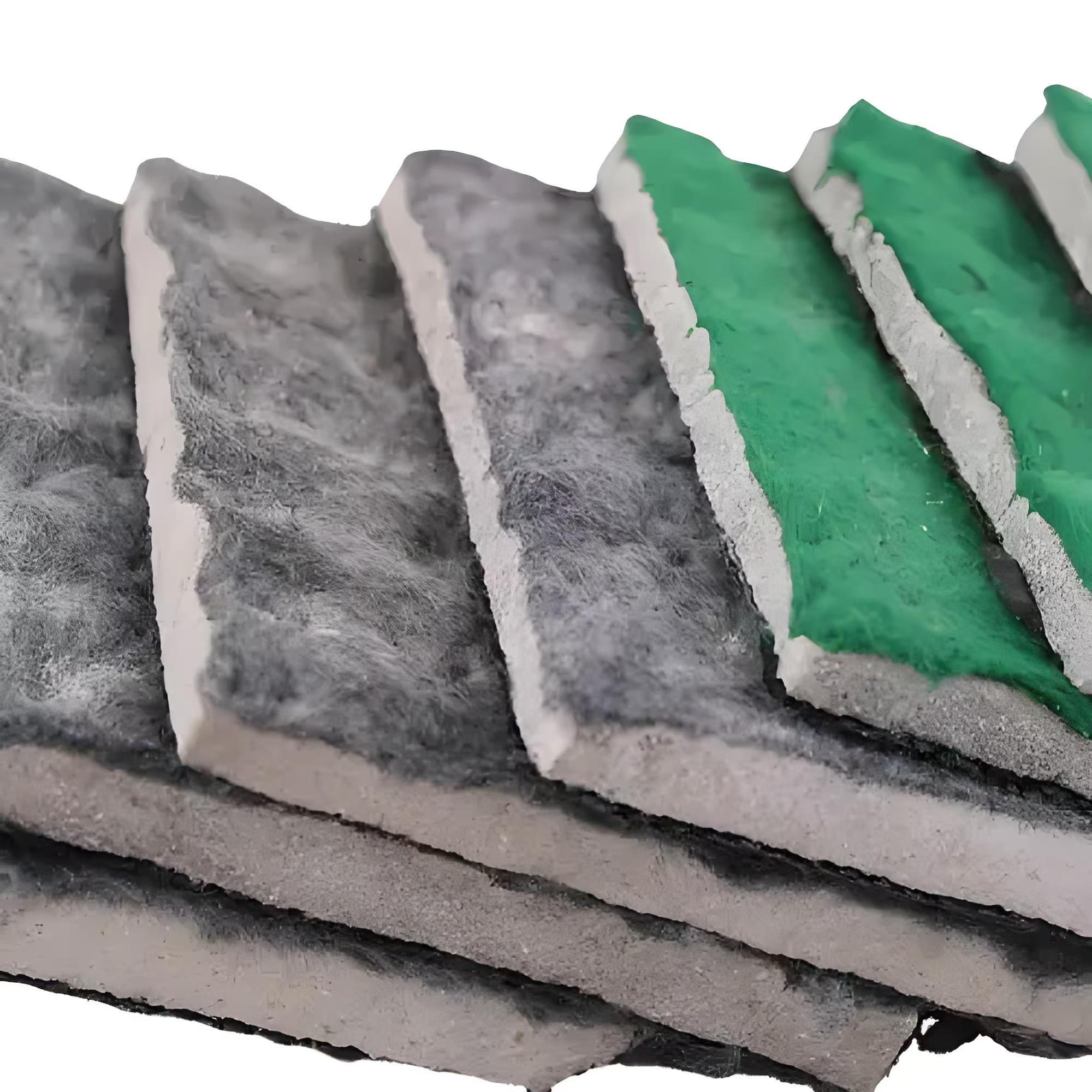

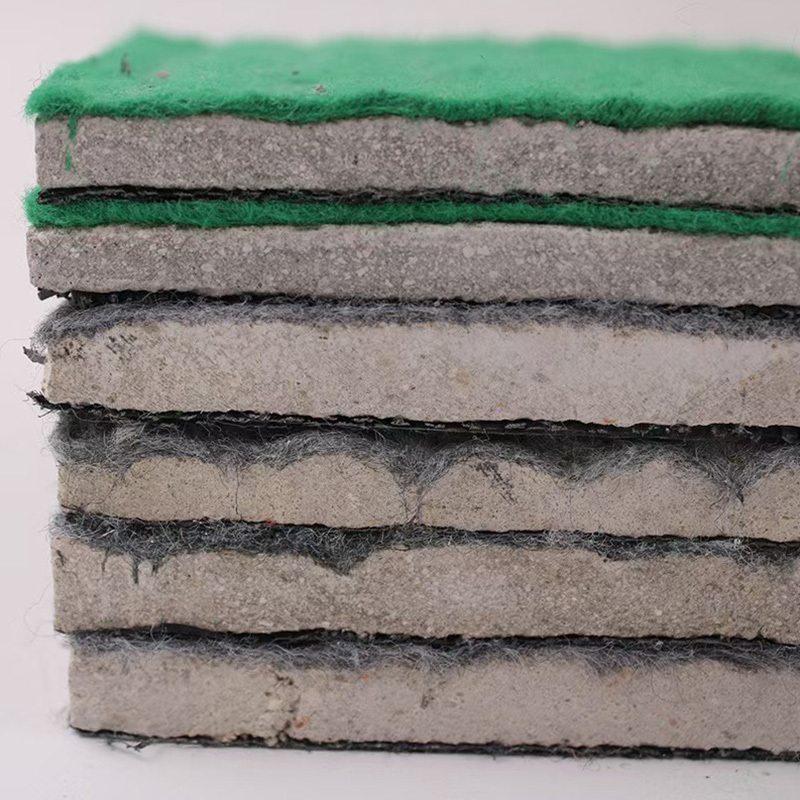

Cement blanket, also known as concrete canvas, is a soft fabric impregnated with cement. Its main components include a three-dimensional fiber composite structure woven from polyethylene and polypropylene filaments, as well as a dry concrete mixture containing a special formula. Its bottom is covered with a polyvinyl chloride (PVC) lining. Cement blankets will undergo hydration reaction when exposed to water, hardening into a thin and durable concrete layer with characteristics such as waterproofing, fireproofing, frost resistance, crack resistance, corrosion resistance, UV resistance, and erosion resistance.

Product specifications and dimensions

Thickness

There are various specifications for the thickness of concrete and cement blankets, with different thicknesses ranging from 5mm to 20mm available for selection.

Width and length

The width of concrete cement blanket is usually between 1 and 4 meters, and the length can be customized according to demand. Special specifications can also be customized according to customer needs.

Indicator parameters

The main indicators of concrete cement blanket include thickness, tensile strength, elongation at break, compressive strength, and water absorption. According to the national standard "Cement Blanket" (GB/T 29490-2013), the thickness of concrete cement blanket should meet the design requirements, the tensile strength should be greater than or equal to the standard specified value, the elongation at break should be greater than or equal to the standard specified value, the compressive strength should meet the standard specified value, and the water absorption rate should be less than or equal to the standard specified value

Tensile strength and elongation at break

Tensile strength and elongation at break are important indicators for measuring the toughness and ductility of materials. Specific values should refer to relevant standards or product manuals.

compressive strength

Compressive strength is a measure of a material's ability to withstand pressure, and typically, after 24 hours, the compressive strength of concrete can reach over 30MPa.

Water absorption rate

The water absorption rate reflects the waterproof performance of the material, and it should be less than or equal to the standard specified value to ensure that the quality will not be affected by moisture during use.

Its main characteristics include:

Waterproof and Fireproof: Cement blankets have excellent waterproof performance, which can prevent moisture infiltration and are suitable for various projects that require waterproof treatment. At the same time, it also has good flame retardant properties, is not easy to burn, and produces very little smoke and toxic gases during combustion.

Lightweight and easy to transport: The cement blanket weighs only 15 kilograms per square meter and can be rolled up like a cloth for convenient storage and transportation. This lightweight feature reduces the reliance on large mechanical equipment, making construction more flexible.

Rapid curing: The cement blanket can quickly undergo hydration reaction upon contact with water, forming a sturdy concrete structure and greatly reducing construction time. This gives cement blankets significant advantages in emergency repairs and rapid construction projects.

Strong durability: Cement blankets have characteristics such as frost resistance, crack resistance, corrosion resistance, UV resistance, and erosion resistance, which can significantly extend the service life of the ground. Its strength and lifespan are comparable to traditional concrete.

Multifunctionality: Cement blankets are suitable for various engineering fields such as slope protection, hardening, waterproofing, etc., and have a wide range of applicability. It can be used in various aspects such as bridges, reservoirs, coastlines, rivers, dams, roads, ponds, electricity, etc., especially performing well in the water conservancy engineering and power industries.

Cost effectiveness: The cost of cement blanket is half that of traditional concrete, which is of great significance for budget control in engineering projects. In addition, using cement blankets can save 90% of materials, shorten the construction period by 60%, and greatly improve construction efficiency.

Overall, cement blanket, as a new type of ground hardening material, has been widely used in various fields due to its lightweight, easy to transport, fast curing, multifunctionality, and cost-effectiveness, and has shown significant advantages.

Main purpose of the product

Post disaster reconstruction: Cement blankets can be used to quickly build temporary shelters after a disaster, providing a fire-resistant and antibacterial environment. They are easy to build and have a long service life.

Water conservancy and irrigation engineering: used for waterproofing and seepage layers of water conservancy facilities such as reservoirs, riverbanks, channels, and drainage ditches, to prevent soil erosion and erosion.

Highway and railway protective belt: used for slope protection and isolation on both sides of highways and railways, to prevent soil erosion and soil weathering, and to improve ground bearing capacity.

Slope protection engineering: used for slope protection engineering such as mountain slopes and riverbanks, to reinforce soil, prevent landslides and erosion, and have better flexibility and adaptability.

Hardening engineering: used for hardening engineering of roads, squares, etc., to improve the bearing capacity and wear resistance of the ground, suitable for hardening engineering in narrow spaces and complex terrains.

Building restoration: used for repairing and strengthening buildings, filling cracks, enhancing wall structures, and adapting to repair needs of various shapes and sizes.

Fish pond slope protection: Cement blankets perform well in fish pond slope protection, with convenient construction and significant effects.

Road construction: Concrete cement blankets can be used to cover the road surface, increase its firmness, smoothness, and durability, prevent mechanical wear and tear, and extend the service life of the road.

Highway maintenance: In highway maintenance, cement blankets can be used to reinforce hardened soil drainage ditches and slopes, improving the level of highway maintenance and the efficiency of waterproofing and water control work

Concrete cement blankets are widely used in river dam protection, ditch and canal protection, fish pond slope protection and other projects, with characteristics such as erosion resistance and anti-seepage. In addition, it can also be used on slopes, in water, and other difficult to reach locations without the need for form or mixing, with minimal equipment requirements.

Concrete cement blanket has the following advantages:

Multifunctionality: Concrete cement blankets can be used in various engineering fields such as slope protection, hardening, waterproofing, etc., and have a wide range of applicability.

Lightweight and easy to transport: The soft nature of cement blankets makes them easy to roll up and transport, reducing reliance on large mechanical equipment.

Flexible and cutting: Cement blankets can be cut according to actual needs, adapting to various shapes and sizes of engineering requirements.

Rapid curing: Cement blankets can quickly undergo chemical reactions when exposed to water, forming a sturdy concrete structure and greatly reducing construction time.

Cost effectiveness: The cost of cement blankets is half that of traditional concrete, which is of great significance for budget control in engineering projects.

Strong durability: Cement blankets can withstand high pressure and weight, are not easily damaged, and have a long service life.

Good impermeability: Cement blankets have excellent waterproof performance, which can effectively prevent water infiltration and protect underground structures from water erosion.

Strong chemical corrosion resistance: Cement blankets have good corrosion resistance to common chemicals and can maintain good stability in acidic and alkaline environments.

Convenient construction: The construction process of cement blanket is relatively simple, without the need for on-site concrete mixing. It only needs to be laid according to the terrain and technical requirements, evenly sprinkled with water or soaked.

Environmentally friendly and low-carbon: The production process of cement blankets adopts low-quality and low-carbon technology, which greatly reduces the amount of materials required compared to traditional concrete materials and consumes less natural resources.

Construction and characteristics of cement blanket

1) The compaction and cleaning of the base layer can be done by manual paving or mechanical lifting, with overlapping paving from downstream to upstream.

2) Fixed: Upstream can be buried in trenches or nailed. About every meter of cement foundation can break nails.

3) The overlapping part of two cement blankets: use U-shaped nails directly. Usually, the overlap is about 10 cm.

4) Curing: When the temperature is not very low, about 80% is cured within 24 hours. Water should be thoroughly watered and drained as soon as it is pressed.

Characteristics of construction site

1: Easy to use, convenient for manual loading, unloading, and transportation. Concrete is scientifically proportioned and does not require on-site configuration. Can solidify and form in mixed water or seawater.

2: Environmental Protection: Cement blanket is a low-carbon technology. The maximum material usage is 93% less than ordinary concrete. The alkali content is limited, the erosion rate is very low, and it has little impact on the ecology.

3: Rapid solidification molding undergoes hydration reaction during watering and hardens within 24 hours. Special formulas can also be used according to customer requirements to achieve rapid solidification or delayed solidification.

4: The material has high strength and looks very thin. In fact, it reached SGS: 38MPa, with a bending strength of about 18MPa and a strength of C25. Therefore, it has good acid and alkali resistance, compression resistance, and bending resistance.

5: The service life can reach 50 years.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.