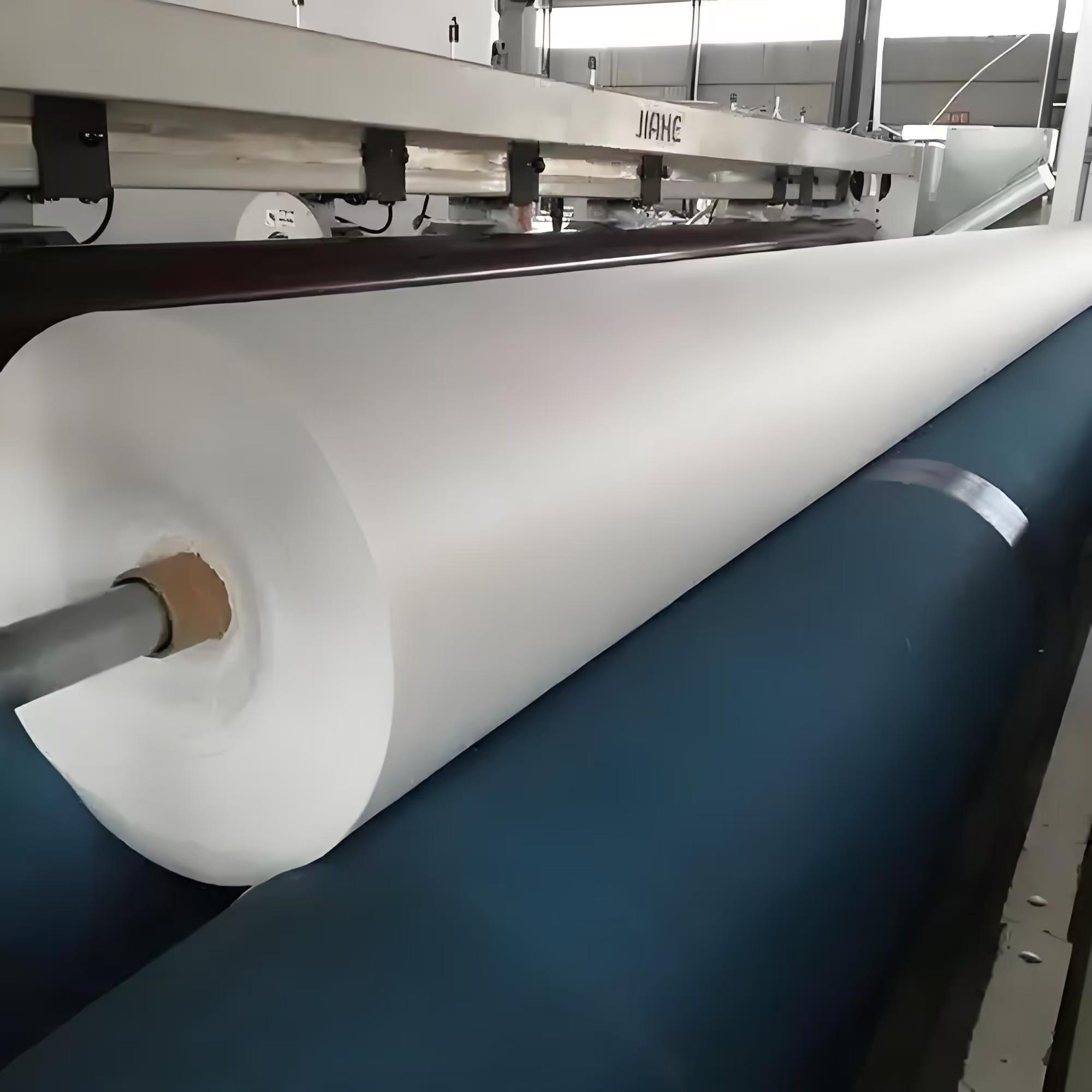

Polyester Filament Geotextile

Classification :

PRODUCT DETAILS

Polyester filament geotextile is a new type of building material used in geotechnical and civil engineering. It is made directly by spinning, needle punching, and solidifying polyester fibers, and has good mechanical properties, heat resistance, light resistance, and excellent corrosion resistance. Its fibers are arranged in a three-dimensional structure, with specifications ranging from 120-800g/m ², suitable for long-term corrosion resistance of various natural soils, moisture, and microorganisms.

Manufacturing method

Polyester filament geotextile is made by the method of forming a network and solidifying polyester filament, including spinning, needle punching, and solidification. This manufacturing method ensures the stability and durability of geotextiles.

Specifications

The weight specification range of polyester filament geotextile is relatively wide, ranging from 120g/㎡ to 800g/㎡. The selection of specific weight specifications depends on the specific application requirements and environmental conditions. For example, 120g/㎡ geotextile is suitable for lighter projects, while 800g/㎡ geotextile is suitable for projects that require higher strength and durability.

Size specifications

The size specifications of polyester filament geotextile include width and length. The width is generally 2m to 6m, and the length is generally 30m to 100m, which can also be customized according to customer needs. In addition, the common width in the market is 6m, and the length is generally 50m.

The main parameters of polyester filament geotextile are as follows:

Unit area mass: ranging from 100g/m ² to 800g/m ².

Thickness: ranging from 0.8mm to 5.5mm.

Fracture strength: The longitudinal and transverse fracture strength ranges from 4.5KN/m to 40.0KN/m.

Fracture elongation: 40% -80%.

CBR bursting strength: ranging from 0.8KN to 7.0KN.

Equivalent aperture: 0.07mm-0.2mm.

Vertical permeability coefficient: ranging from 1.0cm/s to 9.9cm/s.

Tear strength: ranging from 0.14KN to 1.10KN.

Polyester filament geotextile has the following main characteristics:

High strength: Polyester filament geotextile is made of high-strength polyester or polypropylene fibers, which have high tensile strength and puncture resistance, and can effectively enhance the stability and bearing capacity of soil

Permeability: Geotextiles have good permeability, allowing moisture and air to pass through, reducing water accumulation and poor drainage in the soil.

Corrosion resistance: Long filament geotextiles usually have strong resistance to chemical corrosion, which can resist the erosion of acid, alkali and chemical substances in the soil and extend the service life of geotextiles.

Aging resistance: geotextile can resist the influence of ultraviolet radiation and long-term exposure environment after special anti-aging treatment, and has a long service life.

Creep resistance: Polyester filament geotextile has good creep resistance and can resist soil acidity and chemical corrosion.

Ductility: Polyester filament geotextile has good extensibility and can adapt to different soil conditions in different environments.

Easy to construct: Polyester filament geotextile is lightweight, soft, and easy to lay, which can greatly reduce construction difficulty and time.

The application range of polyester filament geotextile is very wide, mainly including:

Polyester filament geotextile is widely used in fields such as water conservancy engineering, highway engineering, railway engineering, airport runways, and port engineering. Specific applications include anti filtration of dams and slope protection, isolation and anti-seepage of channels, foundation isolation of highways and railways, drainage, and soil slope reinforcement.

Roadbed reinforcement: used in infrastructure projects such as highways, railways, airports, etc., as a roadbed reinforcement material to increase the bearing capacity and stability of the roadbed.

Water conservancy engineering: used for slope protection, anti-seepage and other functions of water conservancy projects such as river embankments, dams, reservoirs, etc., to prevent soil erosion and erosion.

Environmental governance: used for anti-seepage and pollution prevention projects in landfills, sewage treatment plants, and other places to control the leakage and diffusion of pollutants.

Landscape: Used for soil fixation and beautification in parks, flower beds, and other places, protecting plant growth and soil structure.

Construction method:

Before using polyester filament geotextile, special attention should be paid to its storage and transportation. Geotextile rolls should be stored on a flat, non waterlogged ground, with a height not exceeding four rolls, covered to prevent UV aging. The integrity of labels and information needs to be maintained. During transportation, it is necessary to ensure that the geotextile roll is not damaged, especially in cases of physical damage or contact with chemical reagents that need to be repaired or discarded.

There are multiple methods to choose from when laying geotextiles. Firstly, when manually rolling and laying, it is necessary to ensure that the fabric surface is flat and leave appropriate deformation allowance. The installation of long or short fiber geotextiles is usually carried out through overlapping, sewing, and welding, with an overlapping width of at least 0.2 meters and a sewing and welding width greater than 0.1 meters. For parts that may be exposed for a long time, it is recommended to use welding or stitching to enhance stability.

The stitching of geotextile must be continuous and tight, with an overlap of at least 150 millimeters, and the distance between the stitching needle and the woven edge must be at least 25 millimeters. The use of resin material for thread stitching requires a thread tension of over 60N and has chemical corrosion resistance and UV protection capabilities equivalent to or stronger than geotextiles. If a 'missing needle' is found, it must be re sutured.

After installation, it is necessary to prevent soil, particulate matter or foreign substances from entering the geotextile layer, so corresponding protective measures need to be taken. The overlapping method of the fabric can be selected according to the terrain and usage requirements, such as natural overlapping, sewing or welding, to ensure overall stability and applicability.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.