Geosynthetic Clay Liners

Classification :

PRODUCT DETAILS

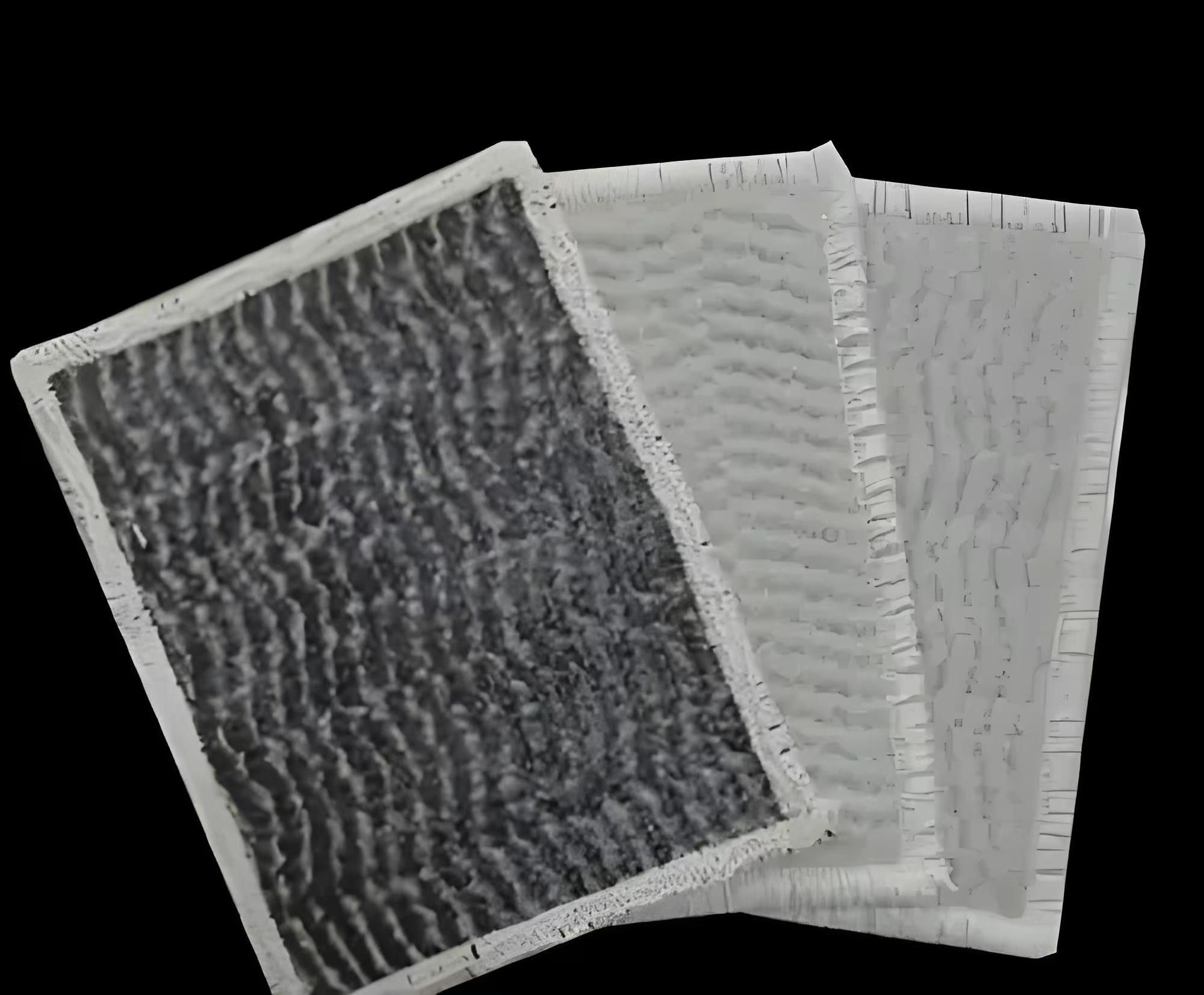

Waterproof blanket, also known as bentonite composite waterproof blanket (GCL), is a new type of geosynthetic material mainly used in anti-seepage engineering. It is made by mixing graded natural sodium based bentonite particles with corresponding additives, and fixed between geotextile and plastic woven fabric through needle punching process to form a blanket like waterproof membrane

The principle and characteristics of waterproof blanket

The waterproof principle of the waterproof blanket is to use bentonite to expand in contact with water to form a gel like waterproof structure. Bentonite can expand more than 24 times when it encounters water, forming a uniform colloidal system with high viscosity and low filtration loss. Under the restriction of two layers of geotextiles, bentonite expands from disorder to order, continuously absorbing water and expanding to compact the bentonite layer, thus achieving waterproof effect

Specification of Bentonite Waterproof Blanket

Bentonite waterproof blankets are divided into three types: ordinary type and laminated type. The quality standards are divided into two types: national standard and ordinary. The specifications of bentonite waterproof blankets are distinguished by length, width, or unit area quality. Common specifications include:

Length: ranging from 20 meters to 60 meters

Width: ranging from 1 meter to 6 meters

Unit area mass: 4000g/m ², 4500g/m ², 5000g/m ², 5500g/m ², 6000g/m ², etc

The specifications and dimensions of waterproof blankets can be customized according to the specific usage scenarios on the construction site.

Indicator parameters:

The main indicators of waterproof blankets include mass per unit area, coefficient of expansion, longitudinal fracture strength, transverse fracture strength, vertical permeability coefficient, peel strength, and resistance to hydrostatic pressure.

Unit area quality: usually requires ≥ 4000g/㎡, specific specifications may include 4000g/㎡, 4500g/㎡, 4800g/㎡, 5000g/㎡, 5500g/㎡, and 6000g/㎡.

Expansion coefficient: required to be ≥ 24 m1/2g.

Longitudinal fracture strength: required to be ≥ 10 KN/m.

Transverse fracture strength: required to be ≥ 10 KN/m.

Vertical permeability coefficient: required to be ≤ 5 × 10 ^ -9 cm/s.

Peel strength: required to be ≥ 65 N.

Anti static water pressure: The anti static water pressure can reach 0.4MPa, and the anti static water pressure of the laminated bentonite waterproof blanket can reach 0.6MPa.

These indicator parameters collectively determine the waterproof performance and durability of the waterproof blanket, which is suitable for various engineering needs such as waste landfills, underground reservoirs, and underground infrastructure construction

The product features mainly include the following aspects:

High waterproof performance: The main function of waterproof blankets is to prevent moisture infiltration, usually made of materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), or butyl rubber, which have excellent waterproof performance.

Chemical stability: Waterproof blankets have good resistance to most chemicals and are not easily corroded, so they can be used in various environments.

Weather resistance: Waterproof blankets can withstand harsh weather conditions such as ultraviolet radiation, temperature changes, and humidity changes, maintaining their performance unaffected.

Wear resistance: The waterproof blanket has a smooth surface, is wear-resistant, and can be laid on rough surfaces without being easily damaged.

Puncture resistance: The waterproof blanket has excellent puncture resistance, which can prevent sharp objects from penetrating and protect the underlying waterproof layer.

Flexibility: Waterproof blankets have good flexibility and can adapt to uneven surfaces, reducing stress concentration during construction.

Easy to install: The waterproof blanket is lightweight and easy to cut and lay, allowing for quick installation and improving construction efficiency.

Environmental friendliness: Some waterproof blanket materials are recyclable and environmentally friendly.

Durability: High quality waterproof blankets have a long service life and can reduce the frequency of maintenance and replacement.

Aging resistance: waterproof blanket can resist natural aging, and can maintain good performance even after long-term use.

Multifunctionality: In addition to waterproofing, some waterproof blankets also have functions such as corrosion resistance, chemical penetration resistance, and filtration.

Economy: Compared with other waterproof materials, waterproof blankets usually have a higher cost-effectiveness and are an economical and practical choice.

The main use of waterproof blanket

Mining: Waterproof blankets are mainly used for anti-seepage in washing pools, heap leaching pools, ash yards, dissolution pools, etc.

Construction engineering: In construction engineering, waterproof blankets are often used for drainage boards, tunnel drainage filtration, roof garden anti-seepage, etc.

Greening project: In greening projects, waterproof blankets can be used for artificial lake anti-seepage, reservoir anti-seepage, and greening planting in saline alkali and gravel land.

Environmental Engineering: Waterproof blankets are widely used in environmental engineering projects such as waste landfills, artificial lakes, ecological river channel renovations, landscape lakes, underground reservoirs, and underground infrastructure construction. They solve problems of sealing, isolation, and leakage prevention with good effectiveness and strong resistance to damage.

Municipal engineering: In municipal engineering, waterproof blankets are used for underground engineering of subways, buildings, and waterproofing of roof reservoirs.

Environmental Protection and Sanitation: In the field of environmental protection and sanitation, waterproof blankets are used for the disposal of household waste landfills, sewage treatment plants, and industrial waste.

Water conservancy: in the field of water conservancy, waterproof blankets are used for seepage prevention, leakage stoppage and reinforcement of Rivers and Lakes, reservoirs and dams.

Gardens and Agriculture: In gardens, waterproof blankets are used for anti-seepage in artificial lakes, golf courses, and ponds; In agriculture, waterproof blankets are used for anti-seepage, anti-corrosion, leak proof, and reinforcement in engineering fields such as petrochemicals, mining, and agriculture.

Composite waterproof blanket is a geosynthetic material specifically used for preventing leakage in artificial lake landscapes, landfills, underground garages, rooftop gardens, water pools, oil depots, and chemical storage yards. It is an anti-seepage liner between GCL (thick compacted clay anti-seepage liner) and polymer material - geomembrane, which has the characteristics of good effect and strong resistance to damage

Construction method of bentonite waterproof blanket:

1. Bentonite waterproof blanket material has a large self weight, and it is recommended to use a shovel machine in conjunction with waterproof blanket lifting tools for transportation and laying. The waterproof blanket can be treated before construction, and the base layer can be divided into soft foundation and hard foundation. Before laying GCL, necessary equipment should be used to level and compact the base layer, with a compaction degree of over 85%. The surface should be smooth and flat, without any rocks or other objects protruding more than 2cm or obvious voids. The surface should be basically dry and there should be no obvious water accumulation. If there is water accumulation, drainage work should be carried out. The radius of rounding for the base layer and external corners should not be less than 30cm. If the radius of the circle exceeds 40cm, even vertically, after anchoring around it, measures should be taken to fix it and ensure compaction without damaging the waterproof pad. There are interconnected pipelines that must be fixed and reinforced with concrete to prevent them from shaking. Anchor trenches must be excavated and compacted as required.

2. Preparation before laying GCL: 1) Conduct cutting analysis, draw the laying sequence and cutting diagram of bentonite composite waterproof pad (GCL). (Auxiliary tools are fully prepared) 2) Check the appearance quality of the bentonite composite waterproof pad (GCL), record and repair any mechanical damage, production trauma, voids, and other defects found. The connection of bentonite waterproof blanket material adopts the overlapping method.

3. When laying bentonite waterproof blankets on slopes greater than 10%, the number of overlaps along the slope length should be minimized as much as possible, and the bentonite pad on the slope must exceed the slope foot line by more than 1500mm.

4. Any equipment used for laying bentonite waterproof blankets cannot be driven on already laid geosynthetic materials. When installing bentonite waterproof blankets, the outdoor air temperature should not be lower than 0 ℃ or higher than 40 ℃.

5. All exposed edges of the bentonite waterproof blanket must be immediately compressed with sandbags or other heavy objects to prevent the bentonite waterproof blanket from being blown by the wind or pulled out of the surrounding anchoring ditch. Bentonite waterproof blanket should not be unfolded in windy weather to prevent it from being blown up by the wind. When laying the bentonite composite waterproof blanket (pad) GCL on the facade and slope, in order to prevent it from sliding, it can be fixed with pins and gaskets. In addition to fixing it with steel nails at the overlapping and edge parts of the waterproof pad, nails should also be added in the middle of the entire waterproof pad according to the flatness to ensure that the waterproof pad is stably and firmly installed on the wall and ground. The nail holes can be treated as needed (when constructing the bentonite composite waterproof pad, the direction of the pad length should be laid parallel to the inclined surface to minimize the phenomenon of falling and accumulating. When connecting the bentonite composite waterproof pad (GCL) with pipeline equipment, the construction method is to pour concrete at the bottom of the pipeline to prevent it from penetrating the pipeline. Shake, fill the gaps around the pipeline with bentonite powder, and then thoroughly seal it. The waterproof pads around the pipeline are tightly tied with fine iron wire.

6. The laying method of bentonite waterproof blanket must ensure direct contact between the bentonite waterproof blanket and the underlying foundation, eliminating wrinkles. Any wrinkling, folding, or arching may cause the same situation to occur in other geotechnical materials in the soil layer. To avoid wrinkling, folding, and arching, we will eliminate these problems by re laying, cutting, and repairing the bentonite waterproof blanket according to the technical specifications.

7. The equipment for bentonite waterproof blanket must be approved by the supervising engineer before use, and unprotected razors or "quick knives" are not allowed. Construction equipment that may damage the bentonite blanket cannot directly act on it. The feasible laying method is to push the soil backwards and spread out the bentonite blanket at the front end of the bulldozer before lifting. If the soil machine leaves a mark on the foundation soil, it should be restored to its original state before the laying work continues.

8. When laying the bentonite blanket, try to minimize the dragging of the bentonite blanket on the foundation to avoid damage to the contact surface between the bentonite blanket and the ground. If necessary, a temporary layer of geotextile can be added to the ground to reduce damage caused by friction during the laying process of the bentonite blanket.

PROJECT CASES

FAQ

Can we visit the factory?

Of course, you are welcome to visit our factory.

Can we give samples?

Of course you can, we provide samples for free in our factory.

Where is the transportation port?

Commonly used ports are Qingdao port, Tianjin port, Shanghai port, or you can specify the port.

How long does it take for delivery?

Production lead time 5 days, and the delivery time will be discussed in detail according to the specific situation.

What payment methods do we support?

Only support TT payment.